Guardians of Raw Milk

Our client is a large-scale dairy production company, primarily responsible for the processing and storage of raw milk. To ensure the quality and safety of dairy products, their production processes demand exceptionally high hygiene standards. In the dairy processing industry, pressure monitoring equipment plays a vital role in both production and storage stages. Particularly during raw milk storage, pressure monitoring not only helps maintain product quality but also prevents unnecessary losses during storage and transportation.

How the Sensor Withstands "High-Pressure Challenges"

The company's production equipment includes multiple raw milk storage tanks and mixing tanks. To ensure sanitation, these tanks are subject to high-pressure water cleaning through a CIP (Clean-In-Place) system. This means that all sensors installed on the equipment must withstand frequent high-pressure cleaning and continue to operate reliably in high-humidity, highly corrosive environments. Without a sufficient protection rating, a sensor's display and internal components can easily be compromised by water infiltration, leading to data inaccuracies and even impacting the stability of the entire production line.

Reliable "Helper" in Pressure Monitoring

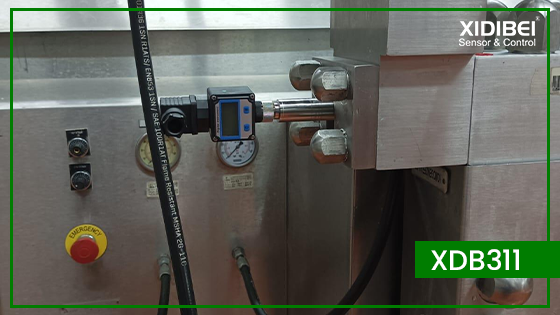

To address the client’s specific needs, XIDIBEI provided a customized XDB311 pressure sensor. In addition to our standard high-precision diffusion silicon sensing chip and 316L stainless steel diaphragm, we equipped the sensor with an LCD display for operators to monitor pressure values in real time. The customized XDB311 sensor boasts an IP65 protection rating, ensuring it remains unaffected by high-pressure cleaning. Furthermore, the 316L stainless steel material and design prevent clogging, even when in contact with high-viscosity media like raw milk, allowing the sensor to maintain stable and accurate measurements consistently.

"Protector" of Efficient Production

Since implementing the customized XDB311 sensor, the client’s operational efficiency has notably improved. With the LCD display, operators can monitor the pressure conditions of the tanks at any time, ensuring pressure stability and responding promptly to any fluctuations. This has reduced breakdowns and downtime caused by cleaning processes and further ensured the quality and safety of raw milk during storage. XIDIBEI's flexible customization capabilities have provided the client with a more efficient and stable production experience, showcasing our professional expertise in meeting unique application requirements.

XIDIBEI is dedicated to providing sensor solutions tailored to specific client needs, safeguarding their production with innovative product designs and flexible customization services.

About XIDIBEI

XIDIBEI is a professional pressure sensor manufacturer dedicated to providing high-quality and reliable sensor products to customers worldwide. With extensive experience in the automotive, industrial, and energy sectors, we continuously innovate to help various industries achieve smarter and more digital futures. XIDIBEI’s products are sold globally and have earned widespread acclaim from customers. We uphold the philosophy of “technology first, service excellence” and are committed to providing superior service to our global clients.

For more information, visit our website: http://www.xdbsensor.com or contact us via email at info@xdbsensor.com.

Post time: Nov-01-2024