In our previous discussion about the Sensor+Test 2024 exhibition, we mentioned that our XDB107 stainless steel integrated temperature-pressure sensor attracted significant interest. Today, let’s delve into what integrated temperature-pressure technology is and its advantages. If you haven’t read our previous article, please click here.

Definition of Integrated Temperature-Pressure Technology

So, what exactly is integrated temperature-pressure technology? Much like smartphones that not only make calls but also take photos, navigate, and access the internet, integrated temperature-pressure technology is a multi-functional technology that enables simultaneous temperature and pressure measurement in a single sensor. These sensors typically use advanced thick-film technology and high-corrosion-resistant materials to ensure stable operation in extreme environments.

With the increasing demand for precise monitoring and control in fields like industrial automation, aerospace, automotive manufacturing, and medical equipment, the application of integrated temperature-pressure technology has become increasingly important. Traditional temperature and pressure measurements typically require two separate sensors, which not only increases installation space and costs but can also complicate data transmission and processing. Integrated temperature-pressure technology simplifies system structure, reduces installation costs, and enhances measurement accuracy and system reliability by combining the functions of two sensors into one. Thus, this technology shows significant potential and advantages in various applications.

Principle of Integrated Temperature-Pressure Technology

Integrated Temperature and Pressure Sensors

Integrated temperature-pressure sensors use advanced thick-film technology to tightly combine temperature and pressure sensors on a single sensor chip. This integrated design not only reduces the sensor’s size but also improves its stability and reliability in various environments. The temperature sensor usually uses high-precision elements like PT100 or NTC10K, while the pressure sensor employs corrosion-resistant materials such as 316L stainless steel, ensuring long-term stable operation in high-temperature and corrosive media.

Data Collection and Processing

Integrated temperature-pressure sensors synchronize the collection and processing of temperature and pressure data through internal circuits. The sensor’s output signal can be analog (e.g., 0.5-4.5V, 0-10V) or standard current signals (e.g., 4-20mA), suitable for various industrial applications. Efficient data processing circuits ensure that the sensor accurately outputs measurement results within a very short response time (≤4ms), meeting real-time monitoring and control requirements.

Working Principle of the Sensor

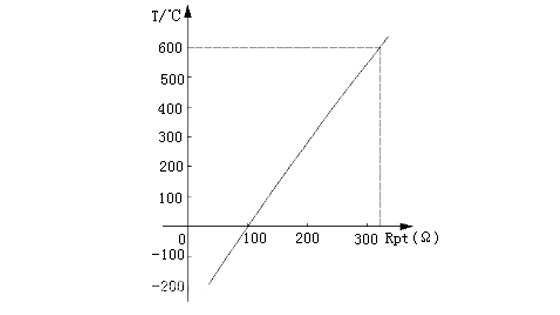

The principles of temperature and pressure measurement are based on the thermoelectric effect and the resistance strain effect, respectively. The temperature sensor measures temperature by detecting changes in resistance caused by temperature variations, while the pressure sensor measures pressure by detecting resistance strain caused by pressure changes. The core of the integrated temperature-pressure sensor lies in integrating these two measurement principles on a single sensor chip and achieving high-precision synchronous measurement and data output through specially designed circuits.

Sensors designed in this way not only have high corrosion resistance and high-temperature resistance but also exhibit excellent long-term stability and reliability, enabling stable operation in various extreme environments.

Advantages of Integrated Temperature-Pressure Technology

Material Advantages: Corrosion Resistance of Stainless Steel

Integrated temperature-pressure sensors use highly corrosion-resistant materials such as 316L stainless steel, ensuring long-term stable operation in various harsh environments. 316L stainless steel not only has excellent corrosion resistance but also features high strength and high-temperature resistance, significantly enhancing the sensor’s reliability under extreme conditions.

Technical Advantages: Application of Thick-Film Technology

The application of thick-film technology in integrated temperature-pressure sensors allows the sensor to maintain high accuracy and stability under extreme temperature and pressure conditions. Thick-film technology not only increases the sensor’s durability but also reduces its size, making it more flexible and convenient in applications.

Improving Measurement Accuracy

By integrating temperature and pressure sensors into a single device, integrated temperature-pressure sensors achieve higher measurement accuracy. This integrated design reduces errors between different sensors, improving data consistency and reliability.

Saving Installation Space

Integrated temperature-pressure sensors reduce installation space by combining temperature and pressure sensors into a single device. This design is particularly suitable for applications with limited space, such as automotive electronics, aerospace, and industrial automation.

Reducing Costs

Since integrated temperature-pressure sensors combine the functions of two sensors, they reduce the number of devices required for purchase, installation, and maintenance, thereby lowering overall costs. Additionally, the use of thick-film technology and stainless steel materials gives the sensors a high cost-performance ratio.

Enhancing Reliability and Stability

Integrated temperature-pressure sensors use high-quality materials and advanced manufacturing technologies to ensure reliability and stability in various harsh environments. The integrated design also reduces interface and connection points between individual sensors, lowering the number of potential failure points and further enhancing system stability.

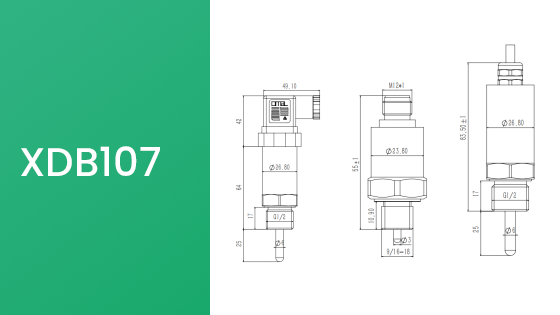

XDB107 Stainless Steel Integrated Temperature-Pressure Sensor

The XDB107 series temperature-pressure sensor module is a versatile device that integrates high-precision temperature and pressure measurement functions, suitable for various industrial applications. This module employs advanced MEMS technology, featuring high reliability and durability, and can operate stably in harsh environments, providing accurate data support.

The sensor module has a compact design, making it easy to install and maintain, and is suitable for applications in confined spaces. Its digital output interface simplifies data transmission and supports multiple communication protocols, ensuring compatibility with various systems. The XDB107 series temperature-pressure sensor module offers an economical and efficient solution, widely used in water treatment, industrial automation, and energy management fields.