With the rapid development of technology, the industrial manufacturing industry is undergoing a profound transformation. Traditional production lines are gradually being replaced by smart devices, and automation and artificial intelligence (AI) have become the core of the future of manufacturing. This transformation is not only about improving efficiency but also about adapting to the rapidly changing market demands. In particular, industrial robots, as the core force of smart manufacturing, are becoming increasingly “intelligent” through AI and sensor technologies, allowing them to better adapt to various production environments. Today, let’s talk about how AI and sensors are making industrial robots smarter.

The Integration of AI and Industrial Robots: From Automation to Intelligence

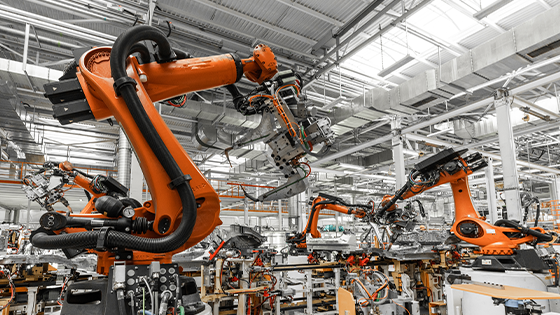

When we think of industrial robots, we probably first think of tasks that are highly repetitive and require high precision, such as assembly, welding, and material handling. These traditional industrial robots perform tasks automatically through preset programs, which are efficient and accurate. However, as production demands become more complex, traditional automation robots are starting to feel a little “clunky.” Now, the introduction of AI technology is making these robots more flexible and intelligent. With AI, robots can not only react to changes in their environment in real-time, but also optimize their actions through machine learning, adapting to more diverse work scenarios. For example, robots can use image recognition to identify different objects and even determine how to perform a task without prior knowledge.

The addition of AI means that industrial robots no longer just “automate” tasks, but instead “think” and “learn” while working. This transformation into intelligence is undoubtedly a huge breakthrough for the manufacturing industry. Can you imagine robots not just following commands but adjusting their behavior based on the situation? That’s the power AI brings!

The Role of Sensor Technology in Industrial Robots

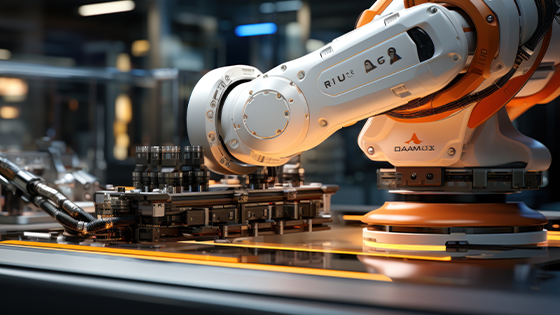

When it comes to making industrial robots smarter, sensor technology plays a crucial role. Imagine if robots couldn’t “see” changes in their environment or “feel” the subtle differences in their operations, how could they make precise decisions? This is where sensors come in, enabling robots to “sense” the world around them. Sensors allow robots to collect real-time data on temperature, pressure, light, sound, and other environmental factors, helping them adjust their movements and optimize their operations.

For example, when a robot is welding on a production line, it needs to control temperature and pressure precisely to ensure the quality of the weld. By installing temperature and pressure sensors, the robot can monitor these key parameters in real-time, avoiding issues like overheating or insufficient pressure. Besides these basic applications, sensors are also widely used in precision operations and quality inspection. For example, with image sensors, robots can “see” every product on the production line, conduct quality checks, and identify and remove defects.

Without sensors, industrial robots would be like robots without “eyes” and “ears,” only able to follow preset programs mechanically. Sensors give robots the ability to “sense” their surroundings, allowing them to make more precise and efficient decisions.

The Synergy Between AI and Sensors: Enhancing Production Efficiency and Precision

When AI and sensors come together, industrial robots are practically given a “super upgrade.” The synergy between these two technologies makes robots not only faster and more efficient but also more capable of precisely adapting to various changes on the production line. In traditional production lines, robots may only rely on preset instructions to perform tasks, but with the changing environment and the increasing complexity of production needs, a single program often isn’t enough. However, when AI and sensors work together, robots can sense every subtle change in their environment and adjust their actions and decisions in real-time, completing more complex and precise tasks.

For example, sensors provide real-time feedback on temperature, pressure, and other factors, enabling robots to respond quickly and adjust the operational parameters during the production process. Meanwhile, AI analyzes this data to optimize production workflows, reducing human error and enhancing efficiency. More importantly, the synergy between AI and sensors greatly enhances production precision. Tasks that used to require manual intervention can now be automated by robots, and done more accurately and consistently.

This intelligent manufacturing approach not only increases production efficiency but also helps businesses significantly reduce costs and improve product quality. The combination of AI and sensors is truly the secret weapon that makes industrial robots “smarter.”

Conclusion: The Future of Smart Manufacturing

Looking back, the combination of AI and sensors is pushing industrial robots toward a smarter and more efficient future. From traditional automation to today’s intelligence, robots are no longer just tools that follow commands; they are becoming smarter, capable of sensing their environment, making adjustments, and optimizing their operations. With the continuous advancement of AI and sensor technologies, we can expect that future industrial robots will become even more flexible, precise, and capable of handling more complex tasks.

This trend of smart manufacturing will not only boost production efficiency and product quality but will also greatly drive innovation across industries. Whether it’s in automotive production, electronics manufacturing, or food processing and pharmaceuticals, the application of AI and sensors will make production more refined, automated, and even capable of personalized production models. The synergy of AI and sensors is redefining the future of smart manufacturing.

As technology continues to develop, we look forward to seeing more industries and companies embrace intelligent robots, boosting their competitiveness and moving toward a more efficient and intelligent manufacturing future. The era of smart manufacturing is already upon us.

Post time: Feb-06-2025