In modern industrial production, pressure monitoring acts like the “heartbeat monitor” of a factory, constantly keeping track of equipment status to ensure everything runs smoothly. However, traditional monitoring devices can often feel like outdated radios—prone to interference and requiring frequent adjustments, making them time-consuming and labor-intensive. The growing demand for more efficient and reliable monitoring solutions has highlighted the need for a fresh perspective on pressure monitoring.

Challenges in Industrial Scenarios: Multi-Faceted Testing in Complex Environments

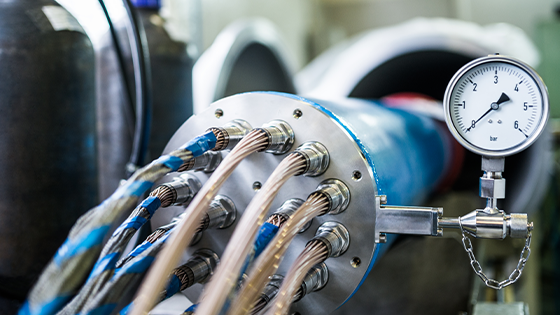

Pressure monitoring equipment is crucial for ensuring safety and efficiency in industrial production, but real-world applications are often far more challenging than expected. In environments like chemical plants and power stations, factors such as strong electromagnetic interference, high-temperature steam, low-temperature liquids, and corrosive media present rigorous challenges to equipment stability and accuracy.

Traditional pressure monitoring devices often struggle in such conditions, leading to issues like data drift and insufficient resistance to interference. These problems can result in inaccurate readings or even system alarms. Furthermore, the complexity of operation and maintenance adds an extra burden for users. Many conventional devices require frequent manual calibration and may lack compatibility with different media types, slowing down production and increasing safety risks. Clearly, modern industries need more precise, stable, and user-friendly monitoring tools to handle these demanding conditions and ensure efficient system operation.

XDB602: The "All-in-One" Solution for Industrial Monitoring

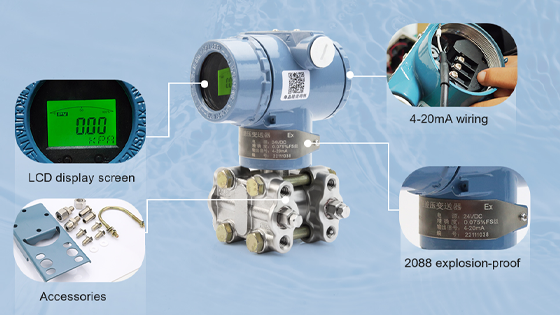

To address these challenges, XIDIBEI introduces the XDB602 intelligent differential pressure transmitter, the ultimate “problem-solver” for industrial monitoring. Combining high precision, stability, and intelligent functionality, the XDB602 is specifically designed to meet the demands of pressure monitoring in complex environments.

The XDB602 offers precision as high as 0.075%FS and advanced digital isolation technology, significantly enhancing its resistance to interference. It delivers reliable data even in environments with strong electromagnetic interference. The built-in temperature sensor effectively minimizes temperature drift, ensuring consistent accuracy under extreme temperature variations.

Its intelligent design stands out as a key feature. With HART communication protocol, users can quickly calibrate and configure the device using a handheld communicator, eliminating the need for tedious manual adjustments. Compatible with gases, liquids, and steam, the XDB602 operates reliably in temperatures ranging from -40°C to 120°C and boasts an IP65 protection rating, making it suitable for harsh industrial conditions.

In essence, the XDB602 is more than just a monitoring tool—it’s a reliable partner in modern industrial production, simplifying complex monitoring tasks and making pressure monitoring effortlessly efficient.

Application Scenario: How the XDB602 Boosts Efficiency in Chemical Plants

Take chemical plants as an example. Pressure monitoring is a critical component not only for ensuring operational safety but also for driving production efficiency. In high-temperature and high-pressure environments, precise monitoring of gases and liquids can prevent equipment overloading or pipe bursts. Such challenging conditions often pose significant difficulties for traditional monitoring devices.

The XDB602 excels in these scenarios. Its high-precision design captures even minor pressure changes in real time, helping chemical plants detect potential issues early and prevent incidents. With superior resistance to interference, it provides stable data in complex electromagnetic environments, ensuring smooth equipment operation.

Moreover, the XDB602 adapts seamlessly to a variety of media, including corrosive liquids, high-temperature steam, and low-temperature gases. This “one-stop” solution reduces the need for frequent equipment changes or adjustments, significantly lowering maintenance costs and optimizing production efficiency.

Its HART communication protocol enables intelligent monitoring, allowing operators to remotely adjust parameters and quickly complete calibration and configuration tasks. This reduces manual intervention while enhancing operational efficiency. This intelligent monitoring approach improves the reliability of production processes and supports the digital transformation of chemical plants.

Conclusion: XDB602—Smarter and More Reliable Industrial Monitoring

Amid increasingly complex industrial environments and rising monitoring demands, the XDB602 intelligent differential pressure transmitter offers comprehensive solutions with its high precision, strong resistance to interference, and intelligent operation. From high-temperature and high-pressure monitoring in chemical plants to harsh conditions in power stations, the XDB602 handles it all, establishing itself as a reliable partner in modern industry.

By addressing the shortcomings of traditional devices and introducing intelligent features, the XDB602 reduces operational complexity and maintenance costs, making monitoring tasks more efficient and convenient. For businesses seeking precise control and stable operations in complex environments, the XDB602 is undoubtedly a trustworthy choice.

Post time: Dec-12-2024