products

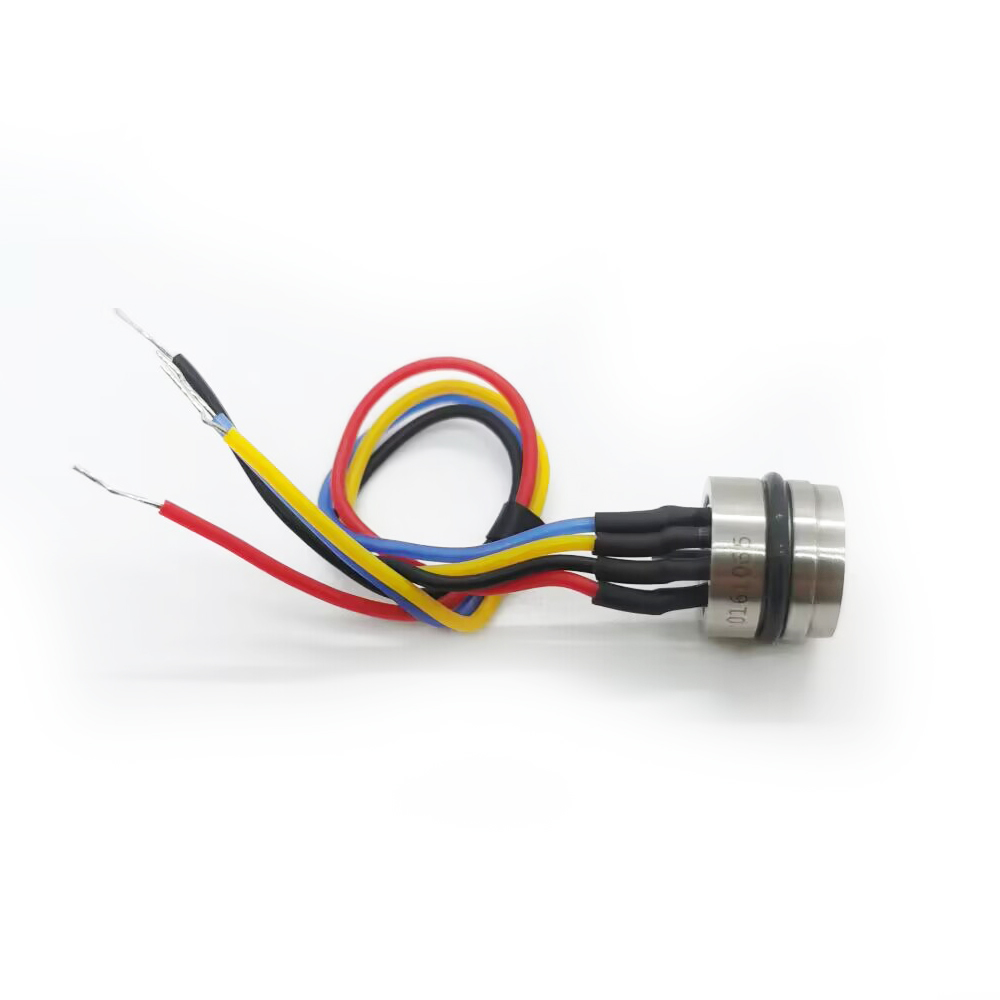

XDB102-4 Diffused Silicon Pressure Sensor

Features

● CE conformity.

● Measuring Range: -100kPa…0kPa~100kPa…70MPa.

● Small Size:φ12.6mm, lower package cost.

● Provide OEM, flexible customization.

● Isolated structure, for a variety of fluid medium pressure measurement.

Typical Applications

● Pressure measurement of automobile engine oil.

● Engineering machinery, water pumps, equipment.

● Industrial process control.

● Urban water supply system.

● XDB102-4 Diffused Silicon Pressure Sensor is especially for engineering machinery and water supply system.

Technical Parameters

|

Structure condition |

||||

|

Diaphragm material |

SS 316L |

Housing material |

SS 316L | |

|

Pin wire |

Kovar/100mm silicone rubber wire |

Back pressure tube |

SS 316L (gauge and negative pressure only) | |

|

Seal ring |

Nitrile rubber | |||

|

Electrical condition |

||||

|

Power supply |

≤2.0 mA DC |

Impedance input |

2.5kΩ ~ 5 kΩ | |

|

Impedance output |

2.5kΩ ~ 5 kΩ |

Response |

(10%~90%) :<1ms | |

| Insulation resistance | 100MΩ,100V DC |

Over pressure |

2 times FS | |

|

Environment condition |

||||

|

Media applicability |

Fluid that is not corrosive to stainless steel and nitrile rubber |

Shock |

No change at 10gRMS, (20~2000)Hz |

|

| Impact |

100g, 11ms |

Position |

Deviate 90° from any direction, zero change ≤ ±0.05%FS |

|

|

Basic condition |

||||

| Environment temperature |

(25±1)℃ |

Humidity |

(50%±10%)RH |

|

| Atmospheric pressure |

(86~106) kPa |

Power supply |

(1.5±0.0015) mA DC |

|

Order Notes

1. To avoid sensor instability, please pay attention to the installation size and installation process to avoid pressing the sensor front within 3 seconds to avoid heat transfer to the sensor.

2. When using a gold-plated cotter pin on a wire, please use a soldering iron below 25W under low temperature soldering.

Ordering Information

|

XDB102-4 |

φ12.6 mm direct assembly type |

|||||

|

|

Assemble and weld ring type |

|||||

|

|

Range code |

Measurement range |

Pressure type |

Range code |

Measurement range |

Pressure type |

|

03 |

0~100kPa |

G / A |

13 |

0~3.5MPa |

G / A |

|

|

07 |

0~200kPa |

G / A |

14 |

0~7MPa |

A / S |

|

|

08 |

0~350kPa |

G / A |

15 |

0~15MPa |

A / S |

|

|

09 |

0~700kPa |

G / A |

17 |

0~20MPa |

A / S |

|

|

10 |

0~1MPa |

G / A |

18 |

0~35MPa |

A / S |

|

|

12 |

0~2MPa |

G / A |

19 |

0~70MPa |

A / S |

|

|

|

Code |

Pressure type |

||||

|

G |

Gauge pressure |

|||||

|

A |

Absolute pressure |

|||||

|

S |

Sealed gauge pressure |

|||||

|

|

Code |

Electrical connection |

||||

|

1 |

Gold-plated kovar pin |

|||||

|

2 |

100mm Silicone rubber leads |

|||||

|

|

Code |

Special measurement |

||||

|

Y |

Gauge pressure type can be used to measure negative pressure Note① |

|||||

|

XDB102-4 -03-G-1-Y the whole spec Note② |

||||||

Note①: When the gauge pressure is measured, it will affect the zero and full value of the sensor. At this time, it is different from the value specified in the parameter table, and it will be fine-tuned on the follow-up circuit.

Note②: We can provide assembly or welding products once we confirmed the sketches you offered.

Order notes

1. To avoid sensor instability, please pay attention to the installation size and installation process to avoid pressing the sensor front within 3 seconds to avoid heat transfer to the sensor.

2. When using a gold-plated cotter pin on a wire, please use a soldering iron below 25W under low temperature soldering.