products

XDB103-3 Ceramic Pressure Sensor Module

Features

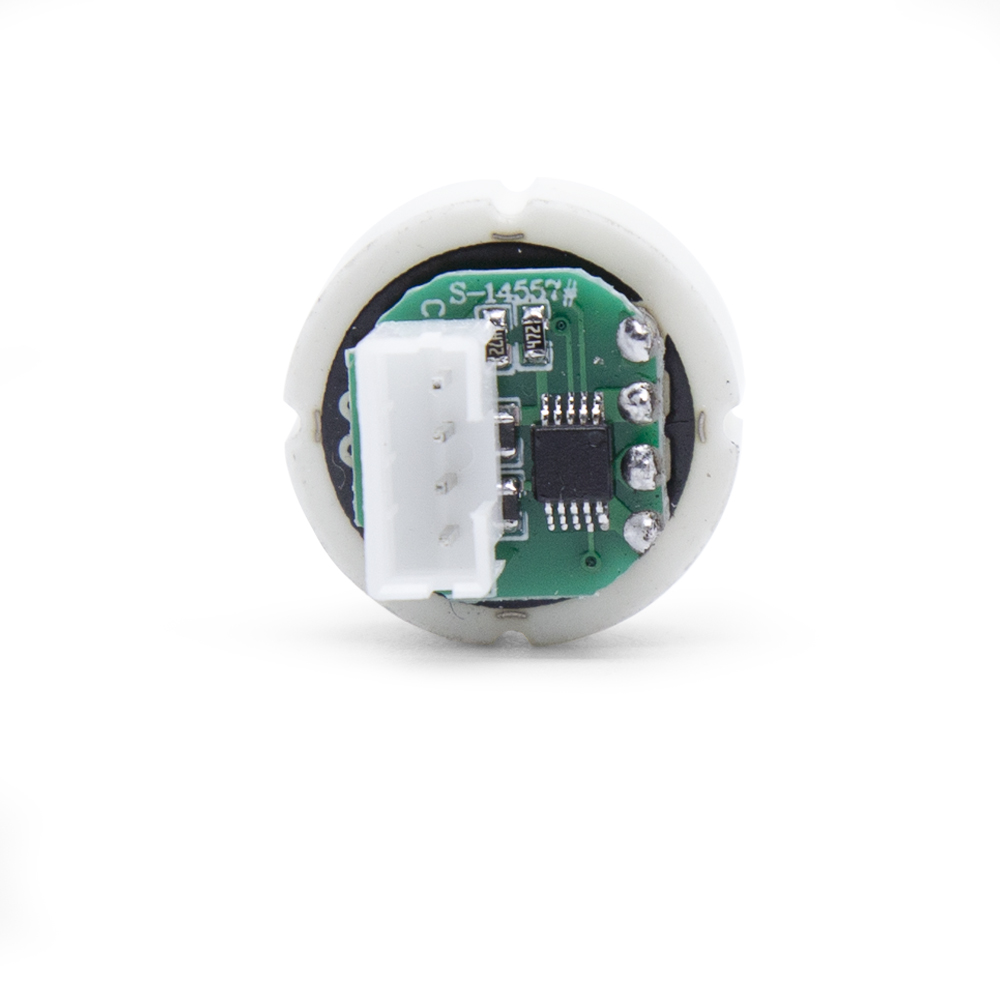

1. Robust Ceramic Diaphragm.

2. With a compact form factor, installation and operation are effortlessly convenient.

3. Engineered with complete surge voltage protection functionality.

4. Excellent corrosion and abrasion resistance.

5. Provide OEM, flexible customization.

Typical Applications

1. Seamlessly integrates into intelligent IoT systems, optimizing energy management and water treatment processes.

2. Plays a pivotal role in medical equipment, agricultural machinery, and testing systems, ensuring precise pressure measurement.

3. Facilitates hydraulic and pneumatic control systems, refrigeration equipment, and industrial automation, elevating operational efficiency.

Important Notice When Mounting The Ceramic Pressure Sensor

Since the sensor is sensitive to humidity, to ensure optimal performance, here are some recommendations for mounting:

● Pre- mounting: Place the sensor in a drying oven at 85°C for at least 30 minutes to remove any moisture.

● During mounting: Ensure that the circumstance humidity is kept below 50% during the mounting process.

● Post-mounting: Take appropriate sealing measures to protect the sensor from moisture.

● Please note that the module is a calibrated product, and errors may occur during the installation process. Before use, it is essential to minimize errors caused by external factors such as the installation structure and other accessories as much as possible.

Technical Parameters

|

Pressure range |

0~600 bar |

Long-term stability |

≤±0.2% FS/year |

|

Accuracy |

±1% FS, Others on request |

Response time |

≤4ms |

|

Input voltage |

DC 9-36V |

Overload pressure |

150% FS |

|

Output signal |

4-20mA |

Burst pressure |

200-300% FS |

|

Operating temperature |

-40 ~ 105 ℃ |

Cycle life |

500,000 times |

|

Compensation temperature |

-20 ~ 80 ℃ |

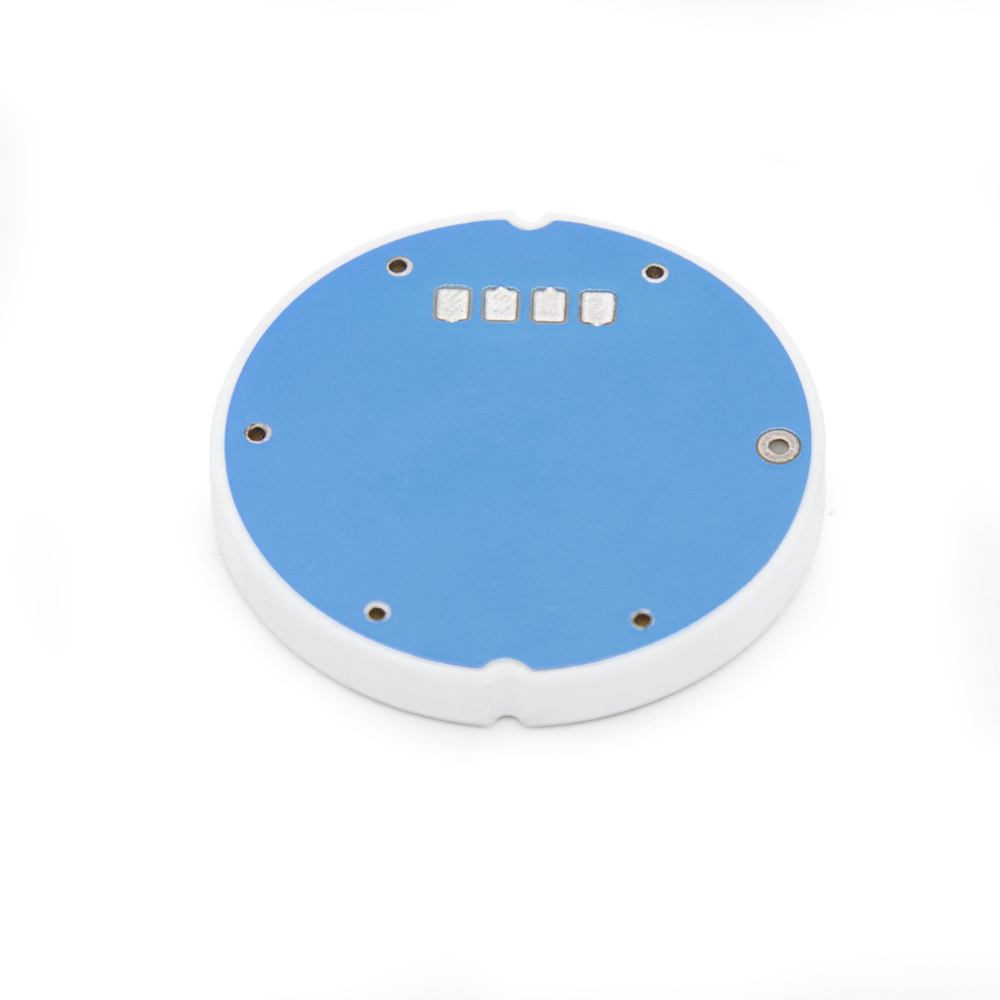

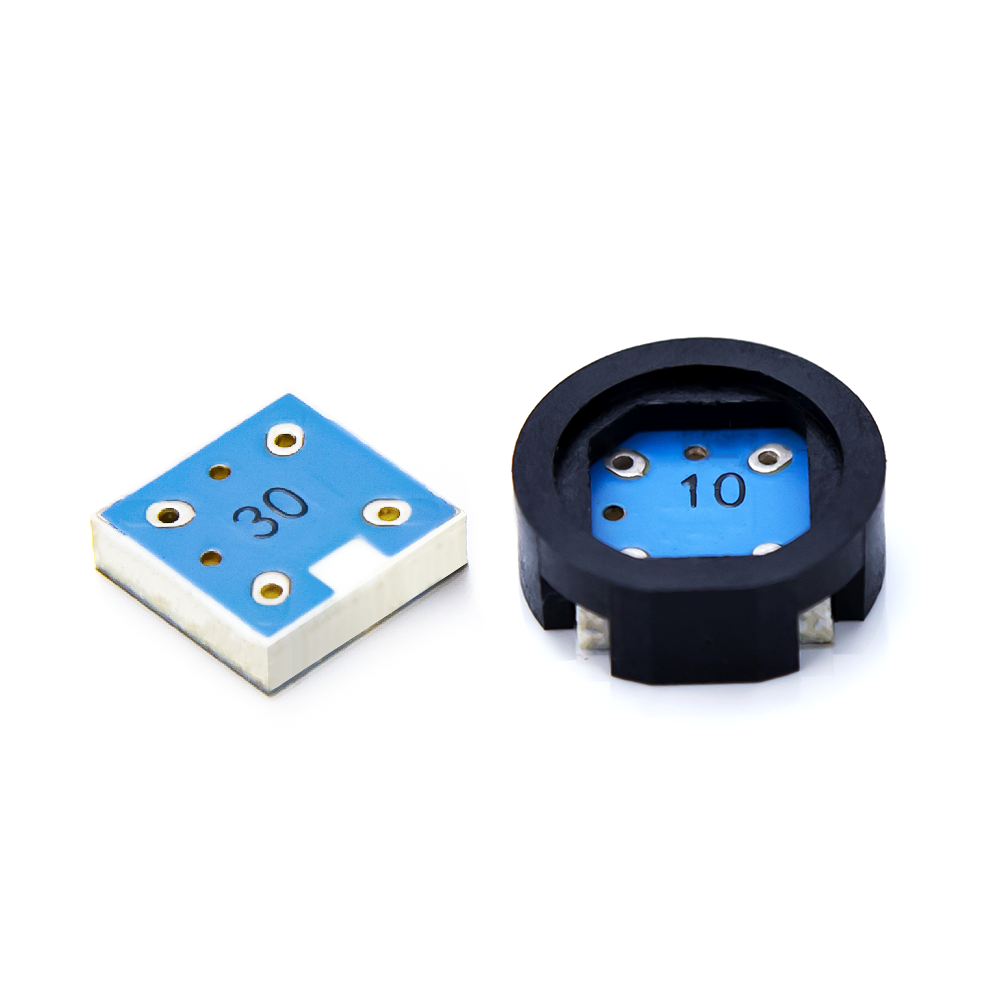

Sensor material |

96% Al2O3 |

|

Operating current |

≤3mA |

Pressure medium |

Media compatible with ceramic materials |

| Temperature drift (zero&sensitivity) | ≤±0.03%FS/ ℃ |

Weight |

≈0.02 kg |

| Insulation resistance | >100 MΩ at 500V | ||

Ordering Information

E.g. XDB103-3- 10B - 01 - 2 - A - c - 01

|

1 |

Pressure range | 10B |

| M(Mpa) B(Bar) P(Psi) X(Others on request) | ||

|

2 |

Pressure type | 01 |

| 01(Gauge) 02(Absolute) | ||

|

3 |

Supply voltage | 2 |

| 2(9~36(24)VCD) X(Others on request) | ||

|

4 |

Output signal | A |

| A(4-20mA) | ||

|

5 |

Accuracy | c |

| c(1.0% FS) d(1.5% FS) X(Others on request) | ||

|

6 |

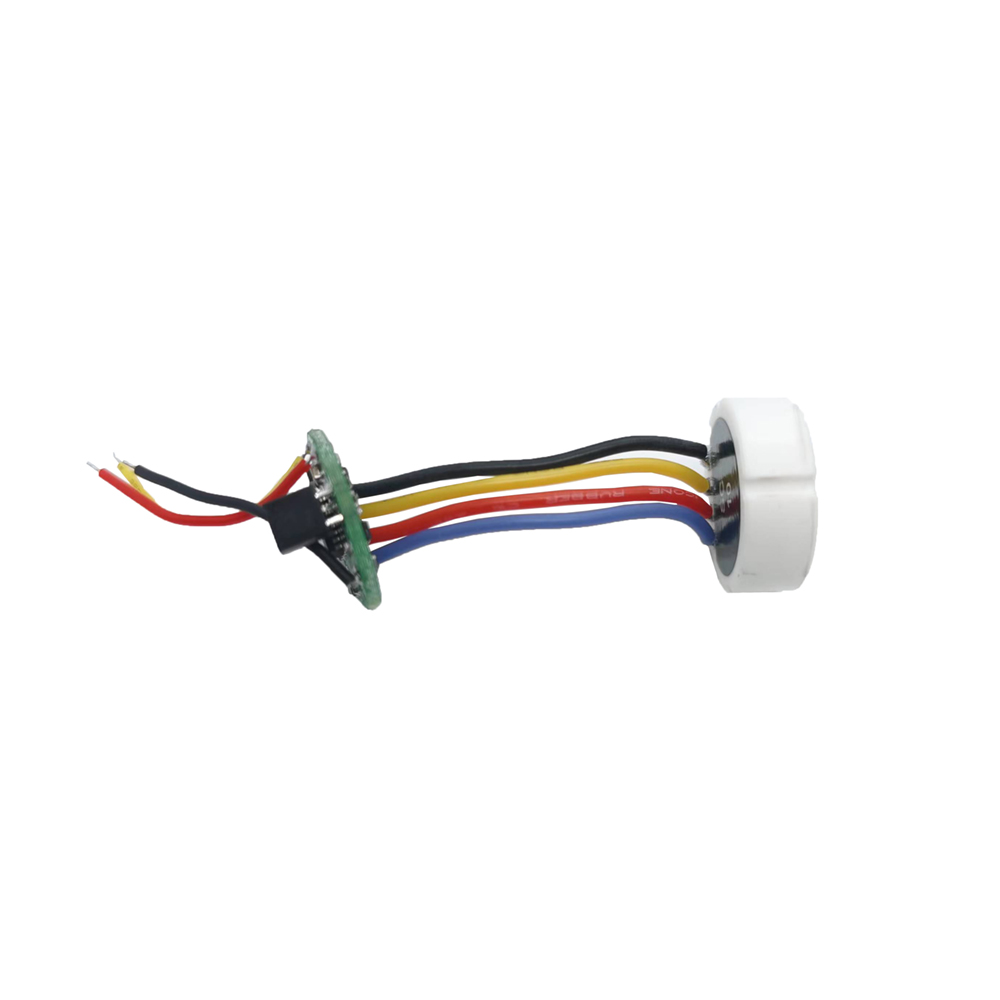

Direct lead wire | 01 |

| 01(lead wire 100mm) X(Others on request) | ||

Notes:

1) Please connect the pressure transducers to the opposite connection for different electric connector.

If the pressure transducers come with cable, please refer to the right color.

2) If you have other requirements, please contact us and make notes in the order.