products

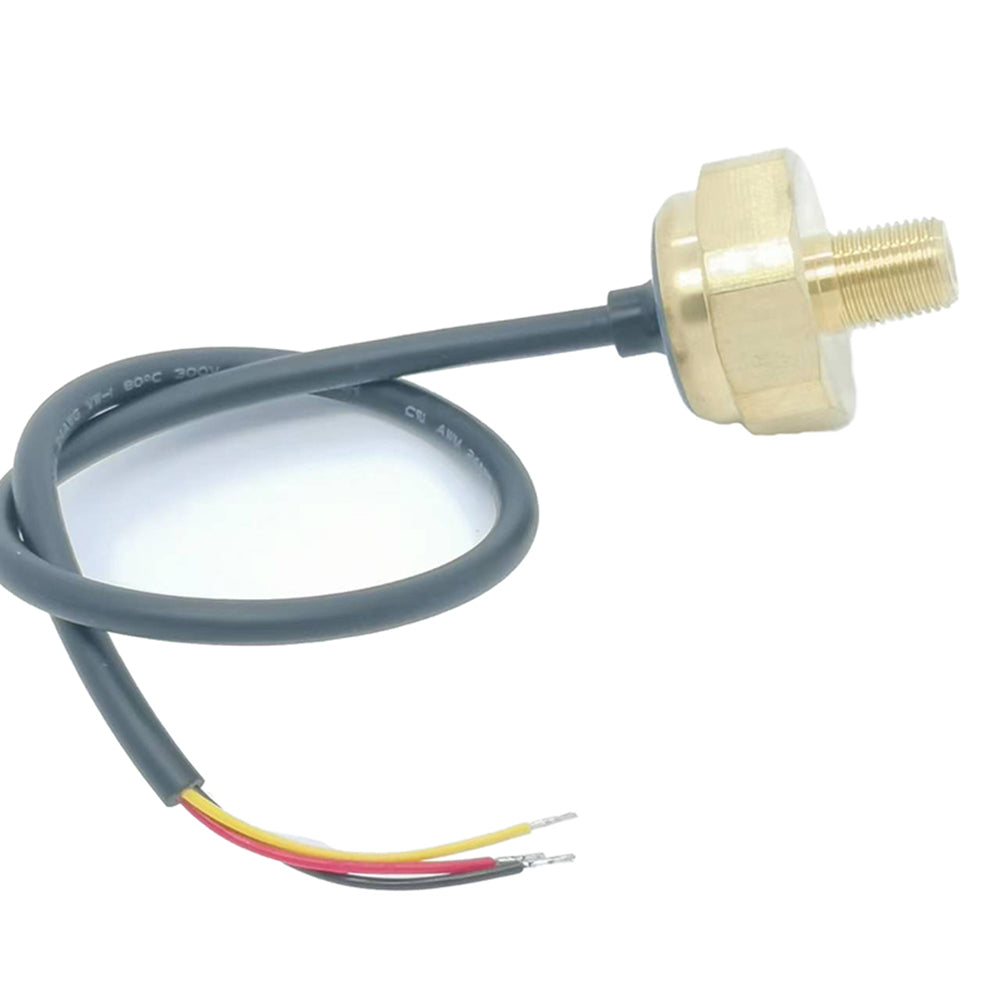

XDB300 Brass Structure Industrial Pressure Transducer

Features

● Low cost and high quality.

● All copper shell structure & compact size.

● Complete surge voltage protection function.

● Short circuit and reverse polarity protection.

● Provide OEM, flexible customization.

● Long-term reliability, ease installation and very economical.

● Suitable for air, oil or other media.

Typical Applications

● Intelligent IoT constant pressure water supply.

● Energy and water treatment systems.

● Medical, agricultural machinery and testing equipment.

● Hydraulic and pneumatic control systems.

● Air-conditioning unit and refrigeration equipment.

● Water pump and air compressor pressure monitoring.

Technical Parameters

| Pressure range | -1~20 bar | Long-term stability | ≤±0.2% FS/year |

| Accuracy |

|

Response time | ≤4ms |

| Input voltage |

|

Overload pressure | 150% FS |

| Output signal | 0.5~4.5V / 1~5V / 0~5V / I2C (others) | Burst pressure | 300% FS |

| Thread | NPT1/8 | Cycle life | 500,000 times |

| Electrical connector | Packard/Direct plastic cable | Housing material | Copper shell |

| Operating temperature | -40 ~ 105 ℃ | Sensor material | 96% Al2O3 |

| Compensation temperature | -20 ~ 80 ℃ | Protection class | IP65 |

| Operating current | ≤3mA | Cable length | 0.3 meter by default |

| Temperature drift (zero&sensitivity) | ≤±0.03%FS/ ℃ | Weight | ≈0.08 kg |

| Insulation resistance | >100 MΩ at 500V | ||

Ordering Information

E.g. XDB300- 150P - 01 - 0 - C - N1 - W2 - c - 01 - Oil

|

1 |

Pressure range | 150P |

| M(Mpa) B(Bar) P(Psi) X(Others on request) | ||

|

2 |

Pressure type | 01 |

| 01(Gauge) 02(Absolute) | ||

|

3 |

Supply voltage | 0 |

| 0(5VCD) 1(12VCD) 2(9~36(24)VCD) 3(3.3VCD) X(Others on request) | ||

|

4 |

Output signal | C |

| B(0-5V) C(0.5-4.5V) E(0.4-2.4V) F(1-5V) G( I2C) X(Others on request) | ||

|

5 |

Pressure connection | N1 |

| N1(NPT1/8) X(Others on request) | ||

|

6 |

Electrical connection | W2 |

| W2(Packard) W7(Direct plastic cable) X(Others on request) | ||

|

7 |

Accuracy | c |

| c(1.0% FS) d(1.5% FS) X(Others on request) | ||

|

8 |

Paired cable | 01 |

| 01(0.3m) 02(0.5m) 03(1m) X(Others on request) | ||

|

9 |

Pressure medium | Oil |

| X(Please note) | ||

Notes:

1) Please connect the pressure transducers to the opposite connection for different electric connector.

If the pressure transducers come with cable, please refer to the right color.

2) If you have other requirements, please contact us and make notes in the order.

Installation Tips

1. Prevent the sensor from contacting with corrosive or overheated media, and prevent dross from depositing in the conduit;

2. When measuring liquid pressure, the pressure tap should be opened on the side of the process pipeline to avoid sedimentation and accumulation of slag;

3. When measuring gas pressure, the pressure tap should be opened at the top of the process pipeline, and the transmitter should also be installed on the upper part of the process pipeline, so that the accumulated liquid can be easily injected into the process pipeline;

4. The pressure guiding pipe should be installed in a place with small temperature fluctuations;

5. When measuring steam or other high-temperature media, it is necessary to connect a condenser such as a buffer pipe (coil), and the working temperature of the sensor should not exceed the limit;

6. When freezing occurs in winter, anti-freezing measures must be taken for the transmitter installed outdoors to prevent the liquid in the pressure port from expanding due to freezing and causing damage to the sensor;

7. When measuring the liquid pressure, the installation position of the transmitter should avoid the impact of the liquid (water hammer phenomenon), so as to avoid the sensor from being damaged by over pressure;

8. Do not touch the diaphragm with hard objects on the sensor probe, as it will damage the diaphragm;

9. When wiring, ensure that the pins are defined, and no short circuit occurs, which may easily lead to circuit damage;

10. Do not use a voltage higher than 36V on the sensor, which may easily cause damage. (The 5-12V specification cannot have an instantaneous voltage higher than 16V)

11. Make sure that the electrical plug is installed in place. Pass the cable through the waterproof joint or flexible tube and tighten the sealing nut to prevent rainwater from leaking into the transmitter housing through the cable.

12. When measuring steam or other high-temperature media, in order to connect the transmitter and the pipe together, a heat dissipation pipe should be used, and the pressure on the pipe should be used to transmit to the sensor. When the measured medium is water vapor, an appropriate amount of water should be injected into the cooling pipe to prevent the superheated steam from directly contacting the transmitter and causing damage to the sensor.

13. In the process of pressure transmission, some points should be paid attention to: there should be no air leakage at the connection between the transmitter and the cooling pipe; be careful when opening the valve, so as not to directly impact the measured medium and damage the sensor diaphragm; the pipeline must be kept unblocked, Prevent deposits in the pipe from popping out and damaging the sensor diaphragm.