products

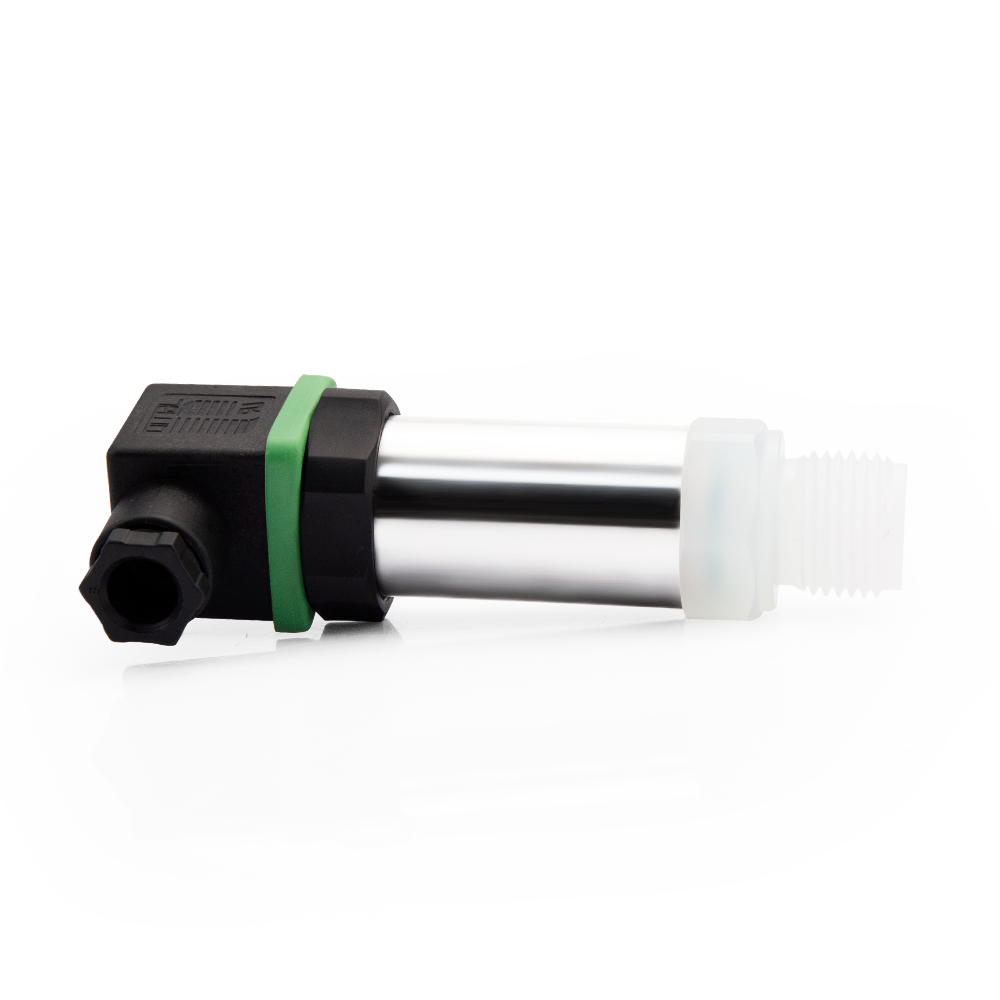

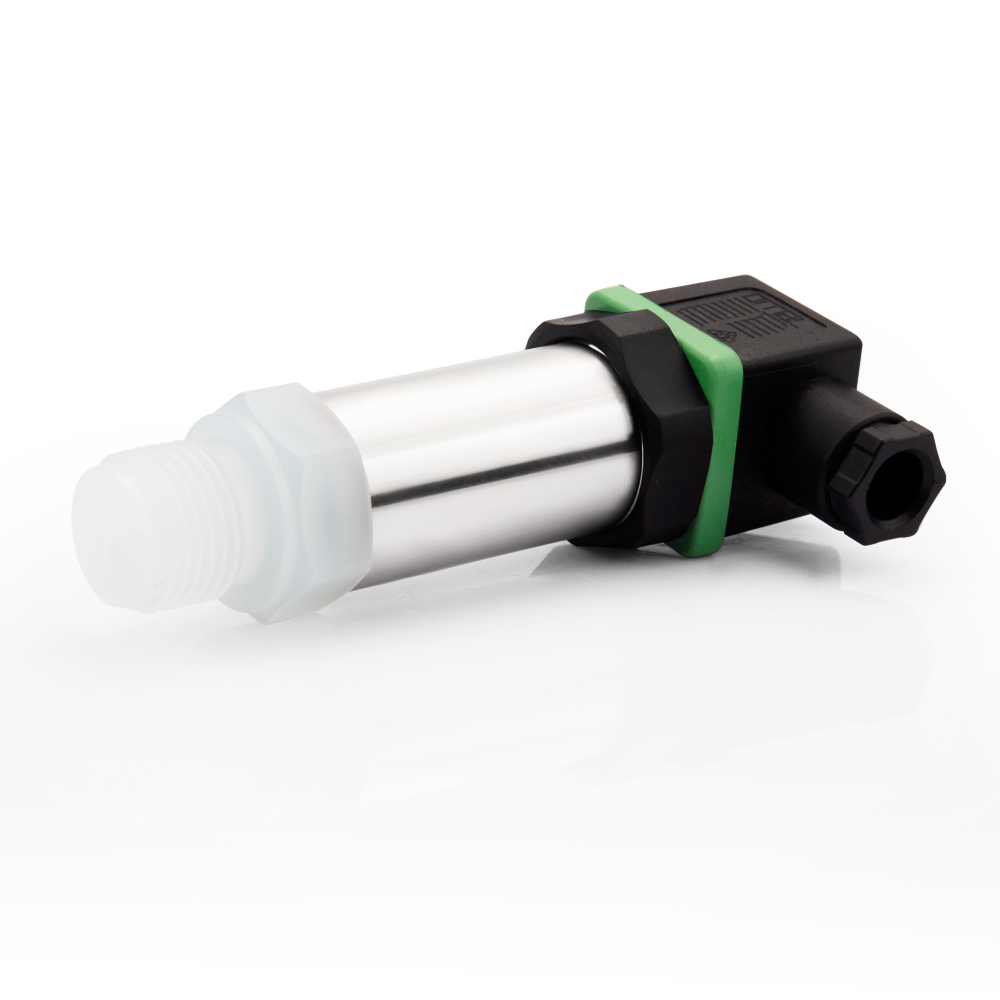

XDB326 PTFE pressure transmitter (anti-corrosion type)

Features

1.High sensitivity, high precision, and good stability

2.Reliable performance and anti-interference

3.PTFE corrosion-resistant thread

Typical applications

1.Industrial process control

2.Petroleum, chemical, and metallurgical industries etc

Parameters

Dimensions(mm) & electrical connection

Installation & Usage

1.XDB326 can be directly installed on the pipeline using an M20 × 1.5 or G1/2 interface, eliminating the need for a mounting bracket.

2.To measure high-temperature media, utilize pressure or cooling devices to maintain the transmitter within its normal operating temperature range.

3.When installing outdoors, place the transmitter in a well-ventilated, dry area to prevent direct exposure to strong light and rain, which can reduce overall performance and lifespan.

4.Ensure proper protection for the cables. In industrial settings, consider using snake skin or iron pipes for shielding or elevating them.

Maintenance & Fault diagnosis

Maintenance:

1.Regularly inspect wiring connections for reliability and cable damage or aging.

2.Periodically clean the guide head and diaphragm based on liquid conditions (be cautious not to damage the diaphragm).

3.Avoid forcefully pulling the cable or using metal or other objects to poke the pressure film.

Fault Diagnosis:

The liquid level transmitter features a fully sealed, integrated design for long-term stability and reliability. In case of issues like no

output, excessively small or large output, or unstable output, follow these steps:

1.Turn off the power.

2.Double-check installation and wiring to ensure they align with the manual's requirements.

3.Verify the correct power supply voltage and ensure unobstructed ventilation.

4.Confirm the overall system functions properly.

5.If the issue persists, it might indicate a transmitter malfunction. Please consult our company for further assistance.