products

XDB803 Series Turbine flow meter

Installation, wiring, use and adjustment

(1) Installation

The installation method of the sensor is determined by the connection method. Flange connection is used. The installation method is shown in Figure 1 and Figure 2. The installation dimensions are shown in Table 1.

1. Filter 2. Front straight pipe section 3. Impeller 4. Preamplifier 5. Housing 6. Rear straight pipe section

1. Ball bearing 2. Front guide 3. Expanding ring 4. Housing 5. Preamplifier 6. Impeller 7. Bearing 8. Shaft

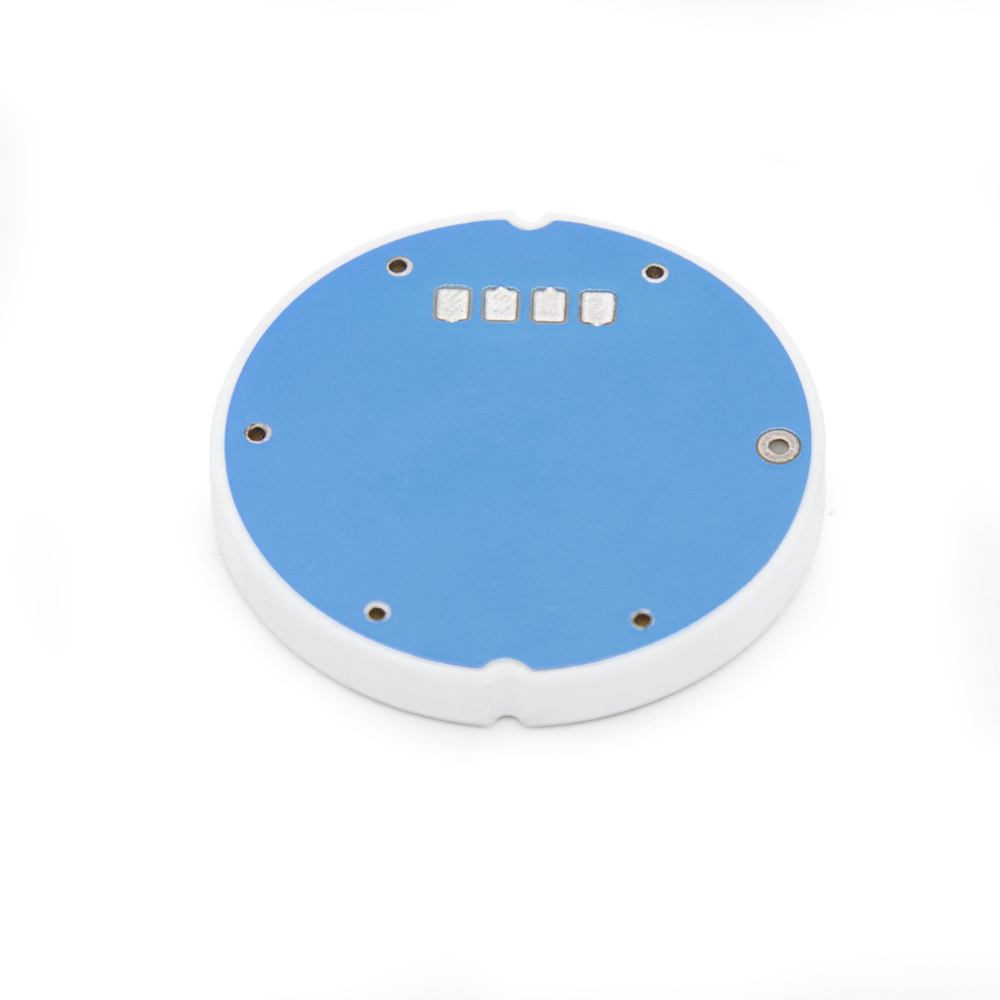

(2) Terminal board wiring instructions

Table 1

|

|

Nominal diameter (mm) |

L(mm) |

H(mm) |

G |

L’(mm) |

D(mm) |

d(mm) |

Number of holes |

|

XDB803-4 |

4 |

275 |

145 |

G1/2 |

215 |

|

|

|

|

XDB803-6 |

6 |

275 |

145 |

G1/2 |

215 |

|

|

|

|

XDB803-10 |

10 |

455 |

165 |

G1/2 |

350 |

|

|

|

|

XDB803-15 |

15 |

75 |

173 |

G1 |

|

|

|

|

|

XDB803-20 |

20 |

85 |

173 |

G1 |

|

|

|

|

|

XDB803-25 |

25 |

100 |

173 |

G5/4 |

|

|

|

|

|

XDB803-32 |

32 |

140 |

175 |

G11/2 |

|

|

|

|

|

XDB803-40 |

40 |

140 |

178 |

G2 |

|

ɸ110 |

ɸ18 |

4 |

|

XDB803-50 |

50 |

150 |

252 |

|

|

ɸ125 |

ɸ18 |

4 |

|

XDB803-65 |

65 |

180 |

278 |

|

|

ɸ145 |

ɸ18 |

4 |

|

XDB803-80 |

80 |

200 |

287 |

|

|

ɸ160 |

ɸ18 |

8 |

|

XDB803-100 |

100 |

220 |

322 |

|

|

ɸ180 |

ɸ18 |

8 |

|

XDB803-125 |

125 |

250 |

347 |

|

|

ɸ210 |

ɸ18 |

8 |

|

XDB803-150 |

150 |

300 |

367 |

|

|

ɸ250 |

ɸ22 |

8 |

|

XDB803-200 |

200 |

360 |

415 |

|

|

ɸ280 |

ɸ22 |

12 |

The sensor can be installed horizontally or vertically. When installed vertically, the fluid direction must be upward. The liquid should fill the pipe without bubbles. When installed, the liquid flow direction should be consistent with the direction of the arrow indicating the flow direction on the sensor housing. The upstream end of the sensor should have a straight pipe section of at least 20 times the nominal diameter, and the downstream end should have a straight pipe section of no less than 5 times the nominal diameter. The inner wall should be smooth and clean, without defects such as dents, scale and peeling. The pipe axis of the sensor should be aligned with the axis of the adjacent pipe, and the gasket used for connection and sealing should not penetrate into the inner cavity of the pipe.

The sensor should be kept away from external electric and magnetic fields, and effective shielding measures should be taken when necessary to avoid external interference.

In order not to affect the normal transportation of the liquid during maintenance, it is recommended to install a bypass pipe at the installation location of the sensor.

When the sensor is installed outdoors, please waterproof the amplifier and plug. The wiring of the sensor and the display instrument is shown in Figure 4.

When the fluid contains impurities, a filter should be installed. The filter mesh is determined according to the flow impurities, generally 20 to 60 mesh. When there is free gas in the fluid, a degasser should be installed. The entire pipeline system should be well sealed.

Users should fully understand the corrosion of the measured medium and strictly prevent the sensor from corrosion.

(3) Use and adjustment

When in use, the measured liquid should be kept clean and free of impurities such as fibers and particles.

When the sensor is first used, the sensor should be slowly filled with liquid, and then the outlet valve should be opened. It is strictly forbidden to impact the sensor with high-speed fluid when the sensor is in a liquid-free state.

The sensor maintenance cycle is generally half a year. When inspecting and cleaning, please be careful not to damage the parts in the measuring chamber, especially the impeller. When assembling, please pay attention to the position relationship between the guide and the impeller.

When the sensor is not in use, the internal liquid should be cleaned, and protective covers should be added at both ends of the sensor to prevent dust from entering, and then stored in a dry place.

The filter should be cleaned regularly when used, and the internal liquid should be cleaned when not in use. Like the sensor, a dust cover should be added and stored in a dry place.

The transmission cable of the sensor can be laid overhead or underground (an iron pipe should be covered when buried underground).