The intelligent monocrystalline silicon pressure transmitter uses an advanced German MEMS technology-produced monocrystalline silicon sensor chip and a globally unique monocrystalline silicon suspended design, achieving internationally leading high accuracy and excellent stability under extreme overpressure conditions. Embedded with a German signal processing module, it perfectly combines static pressure and temperature compensation, providing extremely high measurement precision and long-term stability across a wide range of static pressures and temperature changes.

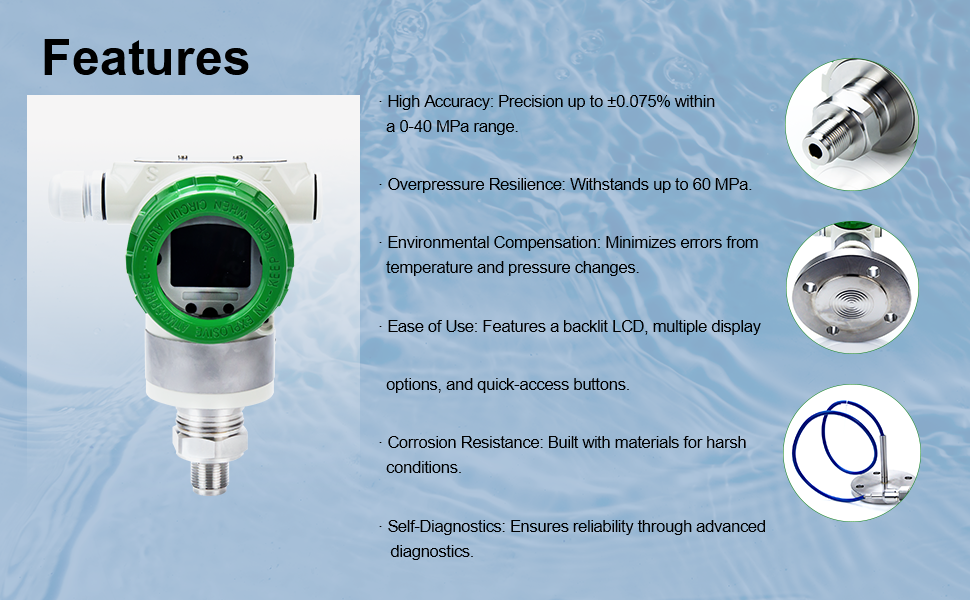

1. High Accuracy: Precision up to ±0.075% within a 0-40 MPa range.

2. Overpressure Resilience: Withstands up to 60 MPa.

3. Environmental Compensation: Minimizes errors from temperature and pressure changes.

4. Ease of Use: Features a backlit LCD, multiple display options, and quick-access buttons.

5. Corrosion Resistance: Built with materials for harsh conditions.

6. Self-Diagnostics: Ensures reliability through advanced diagnostics.

1. Oil and Petrochemicals: Pipeline and storage tank monitoring.

2. Chemical Industry: Precise liquid level and pressure measurements.

3. Electric Power: High-stability pressure monitoring.

4. Urban Gas: Critical infrastructure pressure and level control.

5. Pulp and Paper: Resistant to chemicals and corrosion.

6. Steel and Metals: High precision in furnace pressure and vacuum measurement.

7. Ceramics: Stability and accuracy in harsh environments.

8. Mechanical Equipment and Shipbuilding: Reliable control in stringent conditions.

| Pressure range | -1~400bar | Pressure Type | Gauge pressure and absolute pressure |

| Accuracy | ± 0.075%FS | Input voltage | 10.5~45V DC (intrinsic safety explosion-proof 10.5-26V DC) |

| Output signal | 4~20mA and Hart | Display | LCD |

| Power impact | ± 0.005%FS/1V | Environmental temperature | -40~85℃ |

| Housing material | Cast aluminum alloy and stainless steel (optional) |

Sensor type | Monocrystalline silicon |

| Diaphragm material | SUS316L, Hastelloy HC-276, Tantalum, gold-plated, Monel, PTFE (optional) | Receiving liquid material | Stainless steel |

| Environmental temperature impact |

± 0.095~0.11% URL/10 ℃ | Measurement medium | Gas, steam, liquid |

| Medium temperature | -40~85℃by default, up to 1,000℃ with cooling unit | Static pressure effect | ± 0.1%/10MPa |

| Stability | ± 0.1%FS/5 years | Ex-proof | Ex(ia) IIC T6 |

| Protection class | IP66 | Installation bracket | Carbon steel galvanized and stainless steel (optional) |

| Weight | ≈1.27kg | ||

![XDB605 series Image[2]](https://j575.goodao.net/uploads/XDB605-series-Image2.jpg)

![XDB605 series Image[2]](https://j575.goodao.net/uploads/XDB605-series-Image21.jpg)

![XDB605 series Image[2]](https://j575.goodao.net/uploads/XDB605-series-Image22.jpg)

![XDB605 series Image[2]](https://j575.goodao.net/uploads/XDB605-series-Image23.jpg)

![XDB605 series Image[3]](https://j575.goodao.net/uploads/XDB605-series-Image3.jpg)

![XDB605 series Image[3]](https://j575.goodao.net/uploads/XDB605-series-Image31.jpg)

![XDB605 series Image[3]](https://j575.goodao.net/uploads/XDB605-series-Image32.jpg)

| Model/Item | Specification code | Description |

| XDB605 | / | Pressure transmitter |

| Output signal | H | 4-20mA, Hart, 2-wire |

| Measuring range | R1 | 1~6kpa Range: -6~6kPa Overload limit: 2MPa |

| R2 | 10~40kPa Range: -40~40kPa Overload limit: 7MPa | |

| R3 | 10~100KPa, Range: -100~100kPa Overload limit: 7MPa | |

| R4 | 10~400KPa, Range: -100~400kPa Overload limit: 7MPa | |

| R5 | 0.1kpa-4MPa, Range: -0.1-4MPa Overload limit: 7MPa | |

| R6 | 1kpa~40Mpa Range: 0~40MPa Overload limit: 60MPa | |

| Housing material | W1 | Cast aluminum alloy |

| W2 | Stainless steel | |

| Receiving liquid material | SS | Diaphragm: SUS316L, Other receiving liquid materials: stainless steel |

| HC | Diaphragm: Hastelloy HC-276 Other liquid contact materials: stainless steel | |

| TA | Diaphragm: Tantalum Other Liquid Contact Materials: Stainless Steel | |

| GD | Diaphragm: gold-plated, other liquid contact materials: stainless steel | |

| MD | Diaphragm: Monel Other liquid contact materials: stainless steel | |

| PTFE | Diaphragm: PTFE coating Other liquid contact materials: stainless steel | |

| Process connection | M20 | M20*1.5 male |

| C2 | 1/2 NPT female | |

| C21 | 1/2 NPT female | |

| G1 | G1/2 male | |

| Electrical connection | M20F | M20*1.5 female with a blind plug and an electrical connector |

| N12F | 1/2 NPT female with a blind plug and an electrical connector | |

| Display | M | LCD display with buttons |

| L | LCD display without buttons | |

| N | NONE | |

| 2-inch pipe installation bracket |

H | Bracket |

| N | NONE | |

| Bracket material | Q | Carbon steel galvanized |

| S | Stainless steel |