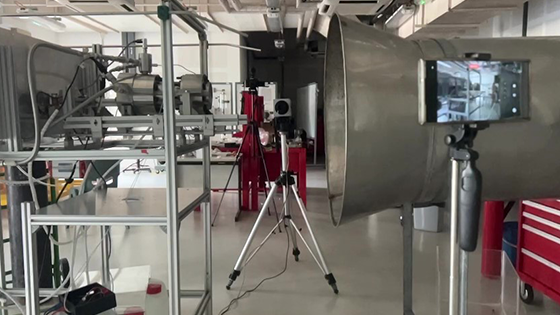

Precision is crucial in the intricate field of rocket science, especially when dealing with complex fuel mixtures. Our client, a prominent research laboratory dedicated to advancing rocket propulsion technology, needed to accurately measure the pressure in a mixture involving rocket fuel, liquid oxygen (LOX), and nitrous oxide (N2O) before combustion.

The mixture of these components is highly sensitive, requiring precise pressure monitoring to ensure safe and efficient combustion. Any deviation in pressure could lead to imbalances, reducing engine performance or even causing critical failures during rocket operation. To address this, the client decided to integrate seven XIDIBEI XDB302 series pressure sensors into their system.

These sensors, known for their precision and long-term stability, were chosen for their ability to withstand the extreme conditions typical of rocket propulsion systems. Encased in a durable stainless steel housing, the XDB302 sensors provided consistent and accurate readings, ensuring that the fuel, liquid oxygen, and nitrous oxide were mixed in the exact required ratios.

By deploying seven XDB302 sensors, the research laboratory achieved outstanding accuracy in monitoring the fuel mixture. This comprehensive approach allowed them to optimize the combustion process, leading to successful rocket engine tests.

This case demonstrates the critical role that XIDIBEI’s XB302 pressure sensors play in the aerospace industry. Through accurate and reliable measurement of complex fuel mixtures, our sensors are helping to drive innovation and ensure the success of cutting-edge rocket propulsion technologies.

Post time: Aug-16-2024