Piezoresistive pressure sensors are a type of pressure sensor that uses the piezoresistive effect to measure pressure. The piezoresistive effect refers to the change in electrical resistance of a material when it is subjected to mechanical strain or deformation. In piezoresistive pressure sensors, a diaphragm or membrane is typically used to convert the applied pressure into mechanical deformation, which in turn causes changes in the resistance of piezoresistive elements.

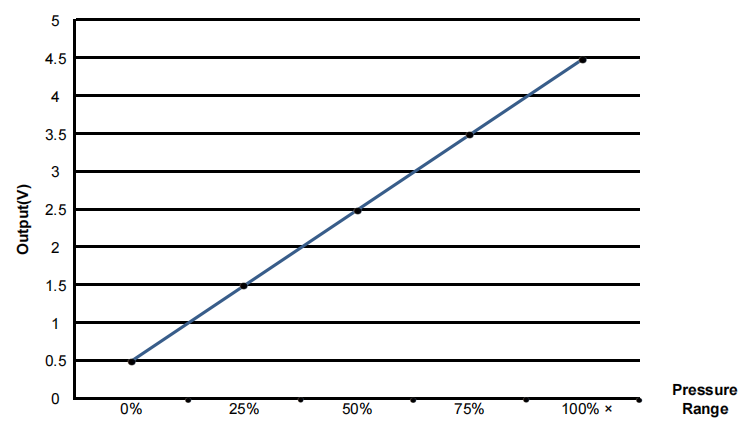

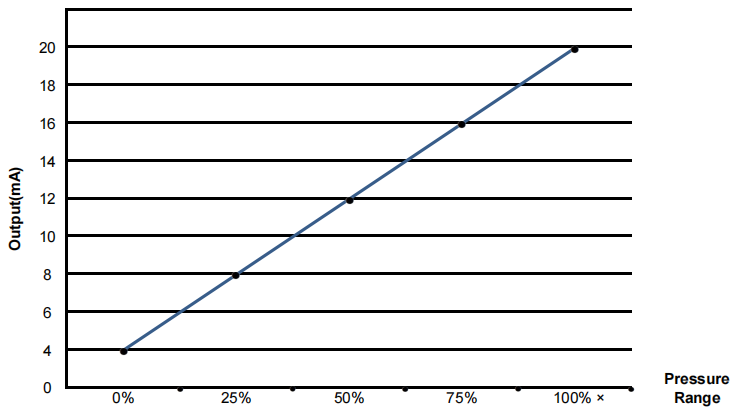

The relationship between pressure and output for a piezoresistive pressure sensor is influenced by the design and material properties of the sensor. Here’s an overview of the general relationship:

1.Direct Proportional Relationship:

In most piezoresistive pressure sensors, there is a direct and linear relationship between the applied pressure and the change in electrical resistance. As pressure increases, the diaphragm or membrane of the sensor undergoes deformation, causing the piezoresistive elements to experience strain. This strain leads to a change in resistance, and this change is proportional to the applied pressure. The change in resistance can be measured using a Wheatstone bridge circuit or other signal conditioning methods.

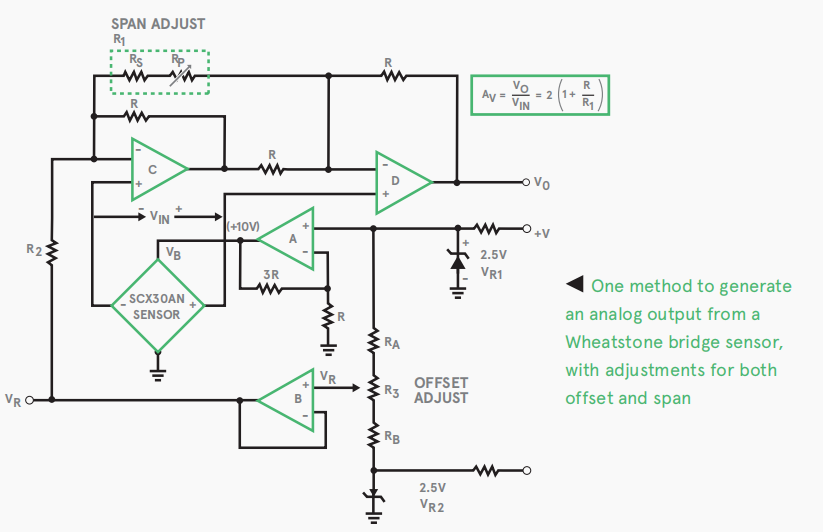

2.Wheatstone Bridge Configuration:

Piezoresistive pressure sensors often utilize a Wheatstone bridge circuit to measure the change in resistance accurately. The bridge circuit consists of multiple piezoresistive elements, some of which are subjected to pressure-induced strain, while others are not. The differential change in resistance between the strained and unstrained elements is used to generate an output voltage that is proportional to the applied pressure.

3.Output Signal Conditioning:

The output of a piezoresistive pressure sensor is typically an analog voltage signal. The voltage output corresponds to the change in resistance and, consequently, the applied pressure. Signal conditioning circuitry might be used to amplify, filter, and calibrate the output signal to obtain accurate pressure readings.

4.Calibration:

Due to manufacturing tolerances and variations in sensor properties, piezoresistive pressure sensors often require calibration to ensure accurate pressure measurements. Calibration involves determining the exact relationship between the sensor’s output voltage and the actual pressure being applied. This calibration can be achieved through testing and comparison against a reference standard.

In summary, the relationship between pressure and output for a piezoresistive pressure sensor is typically linear and proportional. As pressure increases, the sensor’s resistance changes, leading to a corresponding change in the output voltage. The Wheatstone bridge configuration and signal conditioning play important roles in converting the resistance changes into a usable and accurate pressure measurement.