XDB101-5 series flush diaphragm ceramic pressure sensor is the latest pressure pressure core in XIDIBEI, with pressure ranges of 10 bar, 20 bar, 30 bar, 40 bar, 50 bar. It is made of 96% Al2O3, allowing direct contact with most acidic and alkaline media (excluding hydrofluoric acid) without the need for additional isolation protection devices, saving packaging costs. A customized base is employed to ensure exceptional stability during the sensor mounting process.

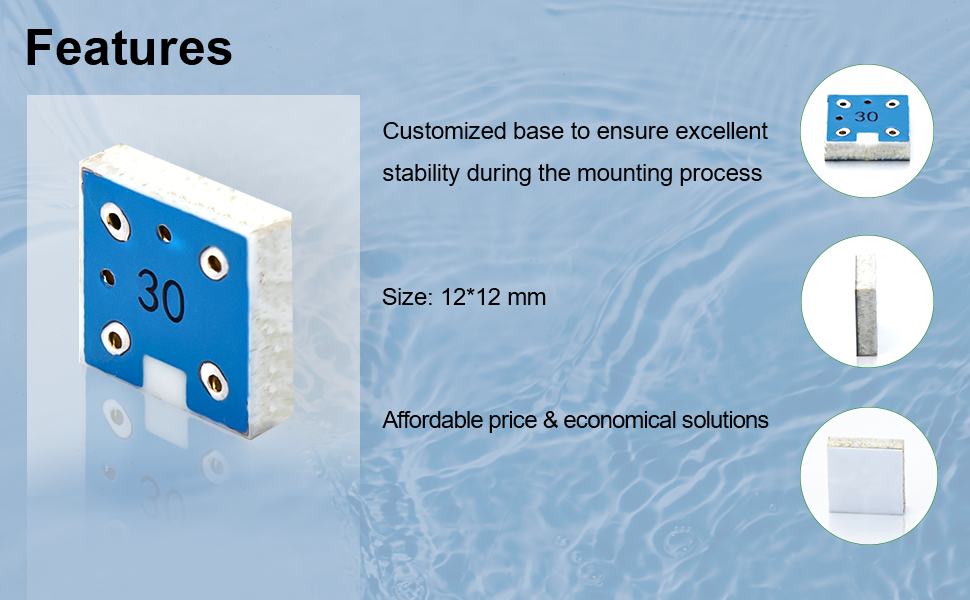

● Customized base to ensure excellent stability during the mounting process.

● Size: 12*12 mm.

● Affordable price & economical solutions.

● Industrial process control.

● Air conditioning refrigerant pressure measurement.

● Liquid, gas or air measurement.

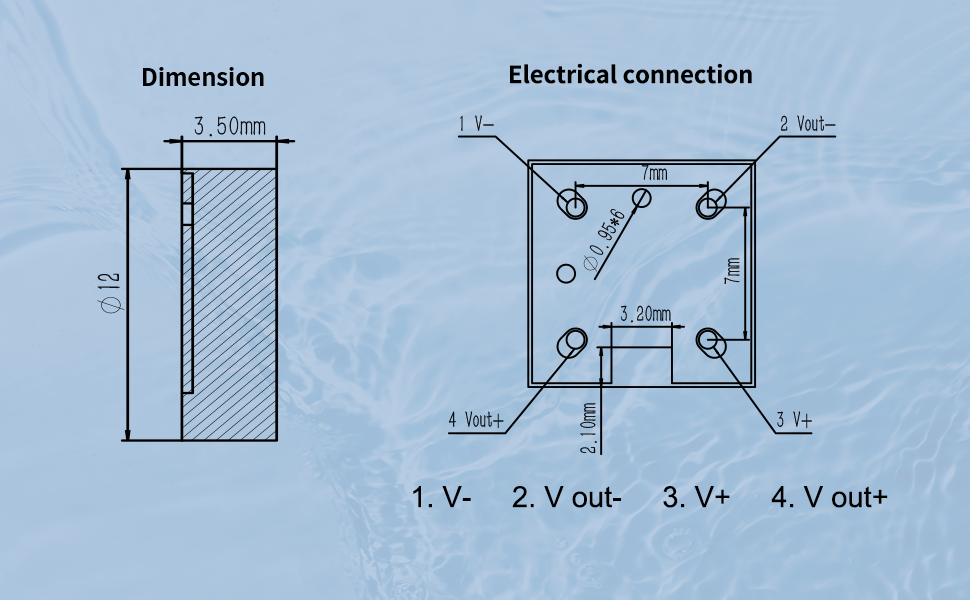

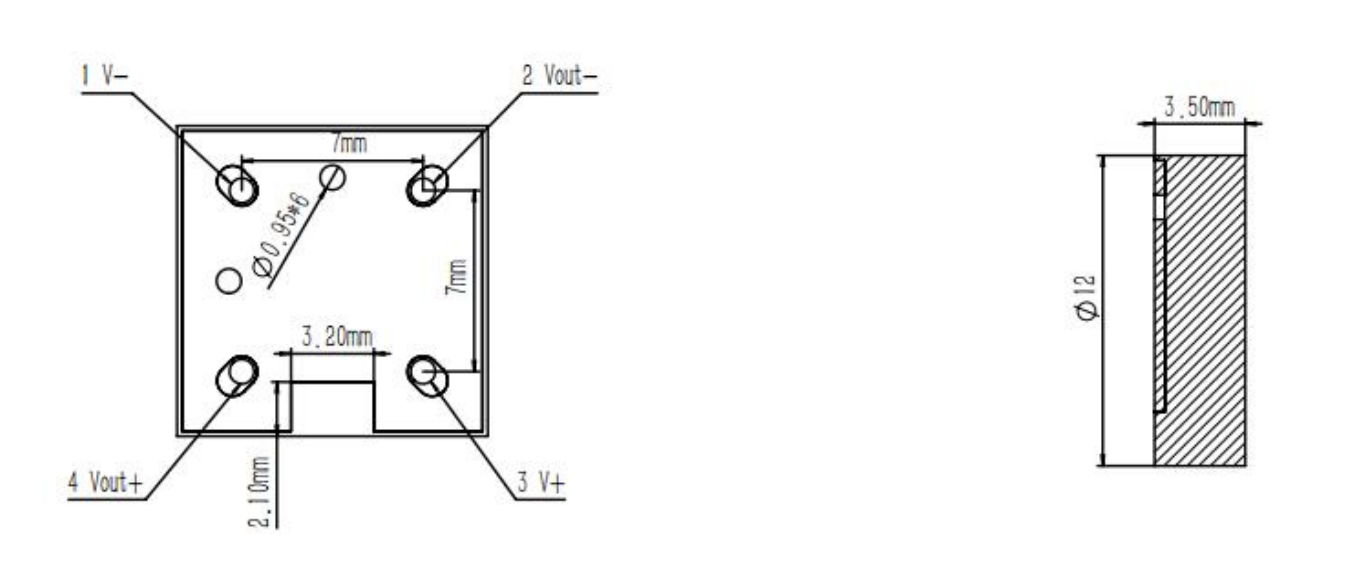

| Pressure range | 10, 20, 30, 40, 50 bar | Size mm (diaphragm*height) | 12*12 mm |

| Product model | XDB101-5 | Supply voltage | 0-30 VDC (max) |

| Bridge road impedance |

|

Full range output | ≥2 mV/V |

| Operating temperature | -40~+135℃ | Storage temperature | -50~+150 ℃ |

| Compensation temperature | -20~80℃ | Temperature drift (zero & sensitivity) | ≤±0.03% FS/℃ |

| Long-term stability | ≤±0.2% FS/year | Repeatability | ≤±0.2% FS |

| Zero offset | ≤±0.2 mV/V | Insulation resistance | ≥2 KV |

| Zero-point long-term stability @20°C | ±0.25% FS | Relative humidity | 0~99% |

| Direct contact with liquid materials | 96% Al2O3 | Overall accuracy (linear + hysteresis) | ≤±0.3% FS |

| Burst pressure | ≥2 times range (by range) | Overload pressure | 150%FS |

| Sensor weight | 12g | ||

The sensor is sensitive to the humidity, here are some recommendations for mounting.

Before mounting, put the sensor into a drying oven with 85°C for at least 30 minutes.

During mounting, make sure that the environment humidity keeps under 50%.

After mounting, appropriate sealing measures should be taken to protect the sensor.

The module is a calibrated product, so errors will inevitably occur during the installation process. Before use, the error caused by external factors (installation structure, other accessories, etc.) should be minimized as much as possible.