XDB401 Pro series pressure transducers are specifically designed for use in coffee machines. They can detect, regulate, and monitor pressure, and convert this physical data into electronic signals. This transducer can remind users to supply water when the water level is low, preventing the machine from running dry and disrupting the coffee-making process. They can also detect high water or pressure levels and raise an alarm to prevent overflowing. The transducers are made from 316L material, which is more compatible with food and can help to ensure that the machine produces perfect espresso by maintaining accurate pressure and temperature.

● Compact, small size.

● Cost-efficient, low consumption.

● Long-term stability and reliability.

● SS316L thread and hexagon part, suitable for food industry.

● Customized-design available, all types of transducers available.

● Intelligent IoT constant pressure water supply.

● Energy and water treatment systems.

● Medical, agricultural machinery and testing equipment.

● Hydraulic and pneumatic control systems.

● Air-conditioning unit and refrigeration equipment.

● Water pump and air compressor pressure monitoring.

● XDB401 SS316L STAINLESS STEEL PRESSURE TRANSDUCER designed for IoT & energy systems, etc.

| Pressure range | – 1~40 bar (optional) | Long-term stability | ≤±0.2% FS/year |

| Accuracy | ±1% FS | Response time | ≤3ms |

| Input voltage | DC 5- 12V | Overload pressure | 150% FS |

| Output signal | 0.5 ~4.5V / 1~5V / 0~5V / I2C (others) | Burst pressure | 300% FS |

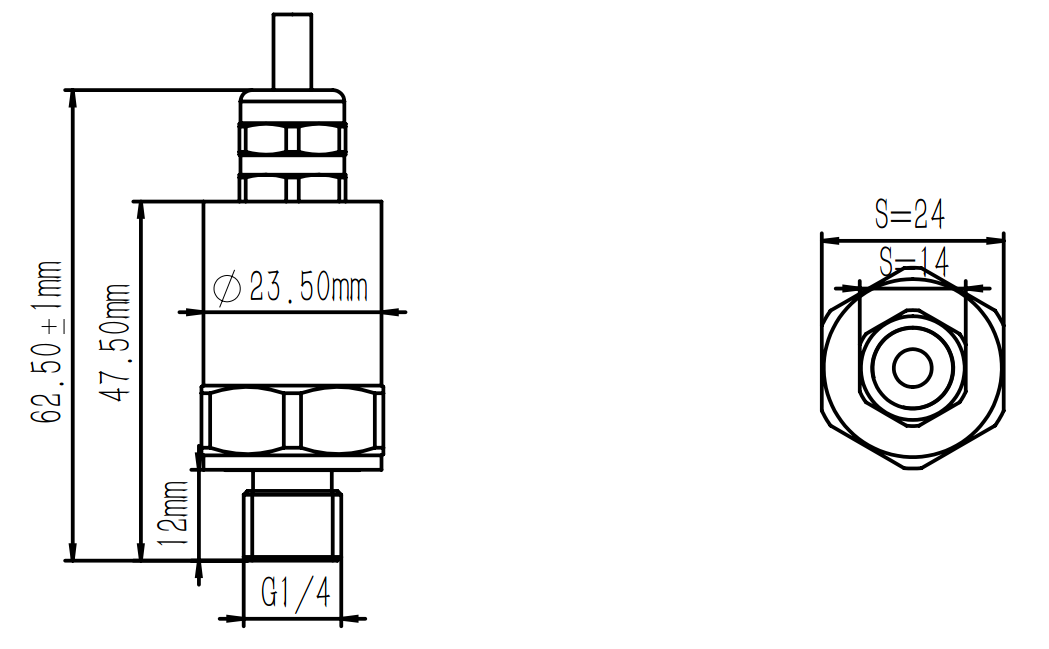

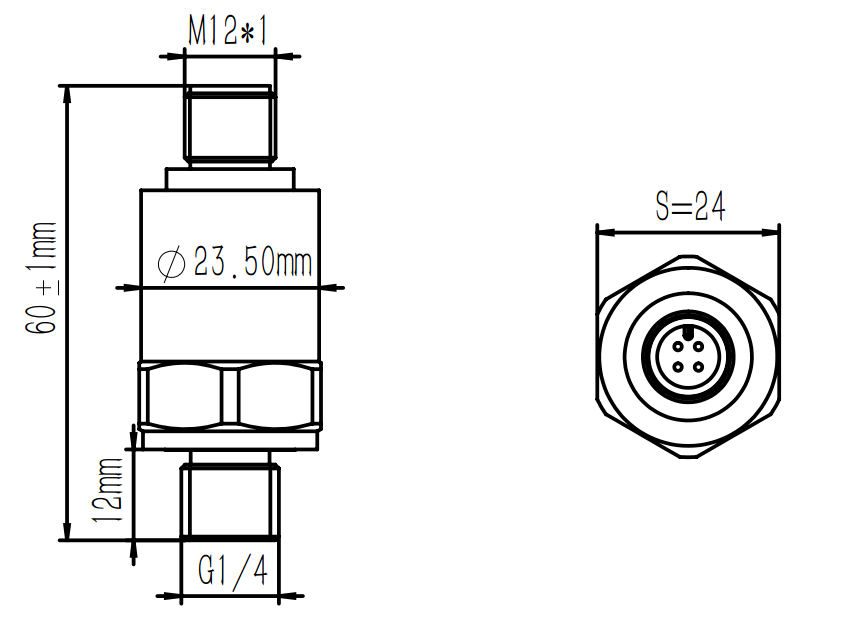

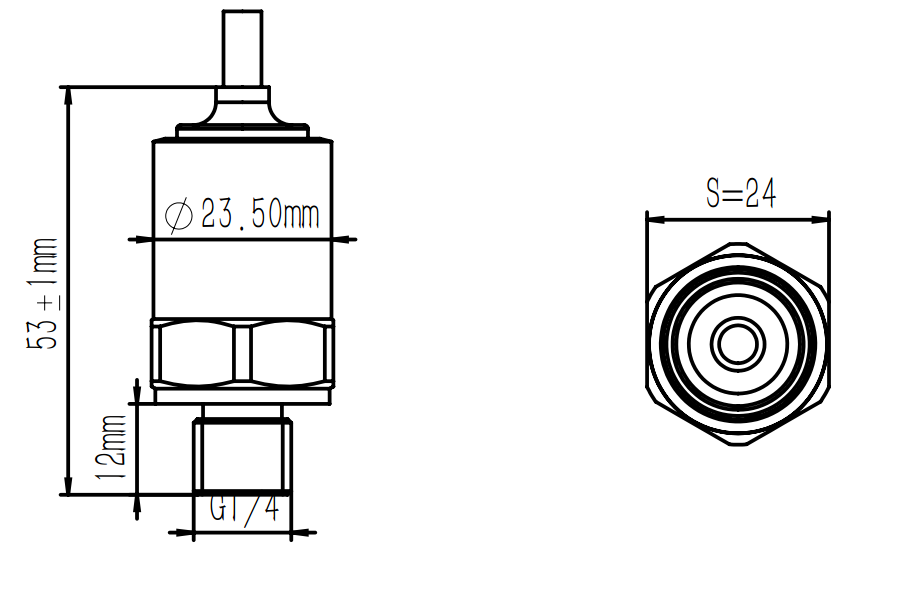

| Thread | G1/4 / G1/2 / G1/8 | Cycle life | 500,000 times |

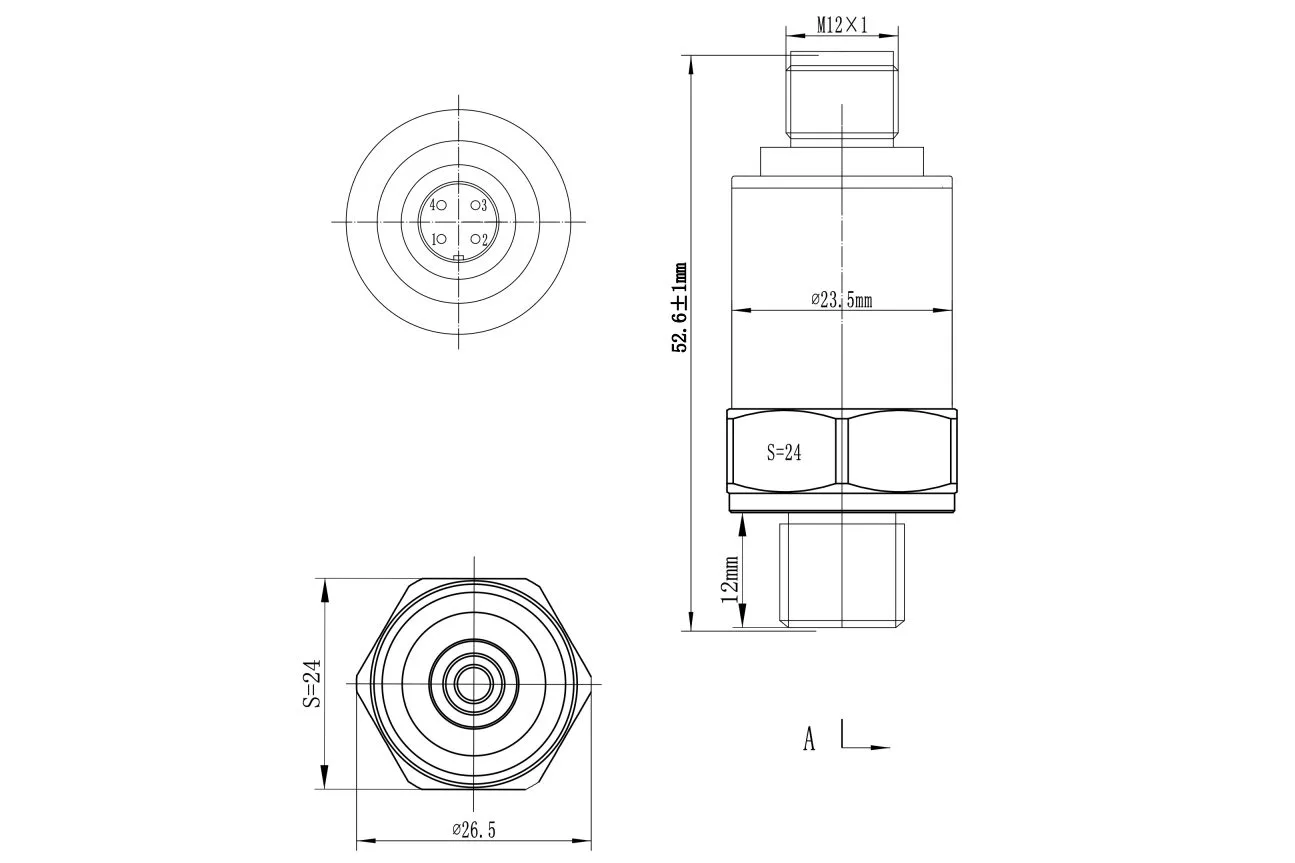

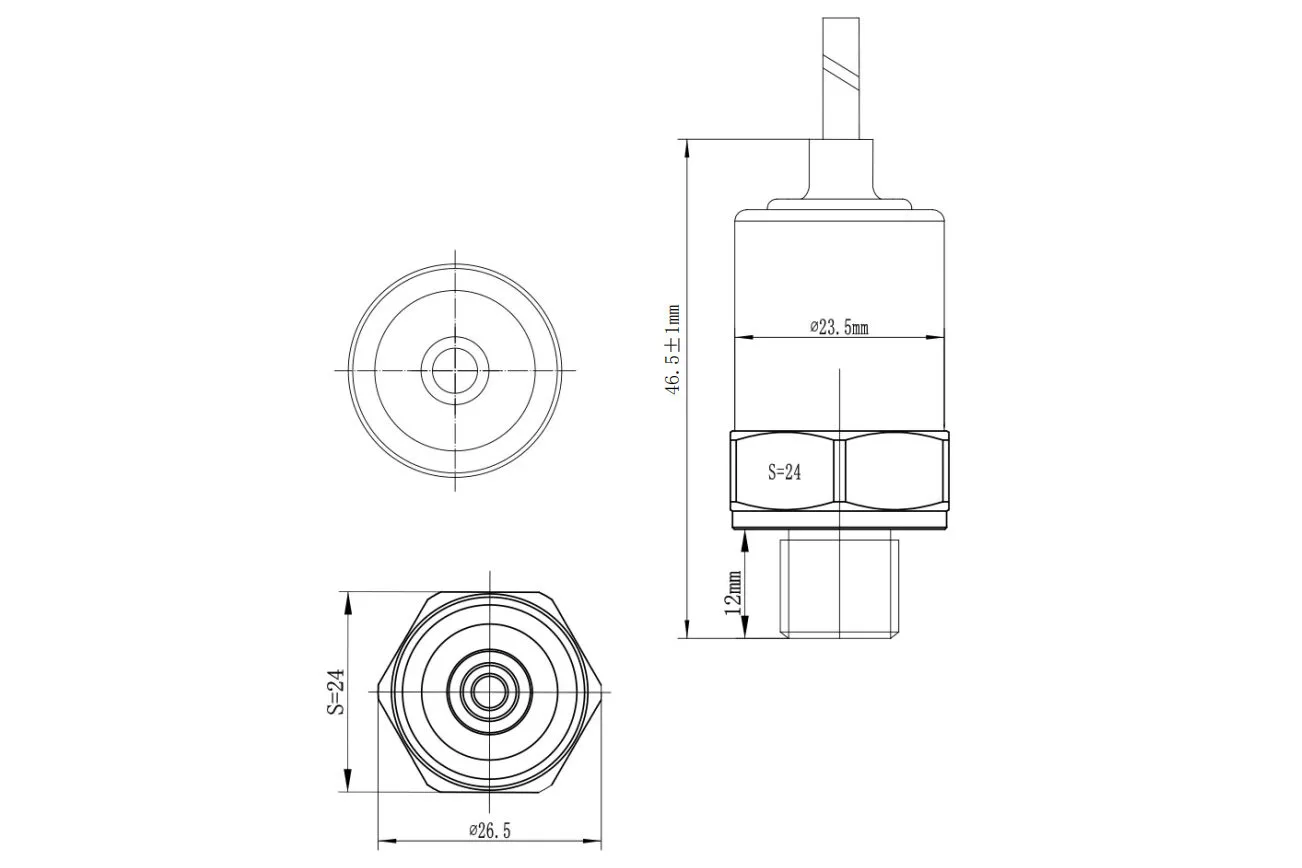

| Electrical connector | Direct plastic cable / M12-4Pin / Gland direct cable | Housing material | SS316L thread and hexagon part; SS304 body |

| Operating temperature | -40 ~ 105 C | Sensor material | 96% Al2O3 |

| Compensation

temperature |

-20 ~ 80 C | Protection class | IP65 / IP67 |

| Operating current | ≤3mA | Cable length | 0.5 meter/ Customized |

| Temperature drift

(zero&sensitivity) |

≤±0.03%FS/ C | Weight | 0.08kg / 0. 15kg / 0. 11kg |

E . g . X D B 4 0 1 – 3 0 B – 0 1 – 3 – A – G 1 – W 4 – c – 0 3 – Wa t e r

| 1 | Pressure range | 30B |

| M(Mpa) B(Bar) P(Psi) K(Kpa) X(Others on request) | ||

| 2 | Pressure type | 01 |

| 01(Gauge) 02(Absolute) | ||

| 3 | Supply voltage | 3 |

| 0(5VCD) 1(12VCD) 2(9~36(24)VCD) 3(3.3VCD) | ||

| 4 | Output signal | A |

| B(0-5V) C(0.5-4.5V) E(0.4-2.4V) F(1-5V) G(I2C) | ||

| 5 | Pressure connection | G1 |

| G1(G1/4) X(Others on request) | ||

| 6 | Electrical connection | W4 |

| W1(Gland direct cable) W4(M12-4Pin) W5(Hirschmann DIN43650C)W7(Direct plastic cable) X(Others on request) | ||

| 7 | Accuracy | c |

| c(1.0% FS) X(Others on request) | ||

| 8 | Paired cable | 03 |

| 02(0.5m) 03(1m) 04(2m) 05(3m) X(Others on request) | ||

| 9 | Pressure medium | Water |

| X(Please note) | ||

Notes:

1) Please connect the pressure transmitter to the opposite connection for different electric connector.

If the pressure transmitters come with cable, please refer to the right color.

2) If you have other requirements, please contact us and make notes in the order.