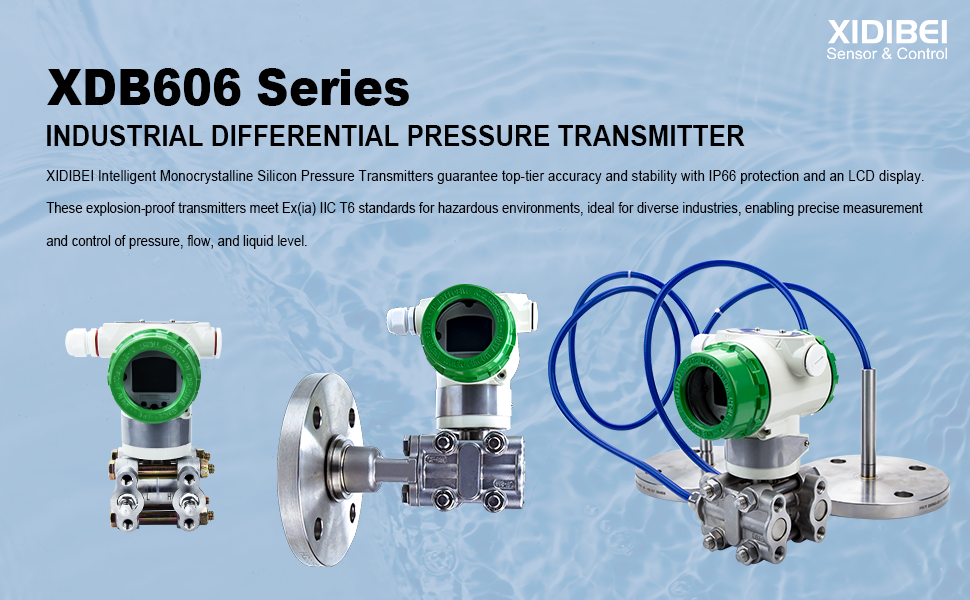

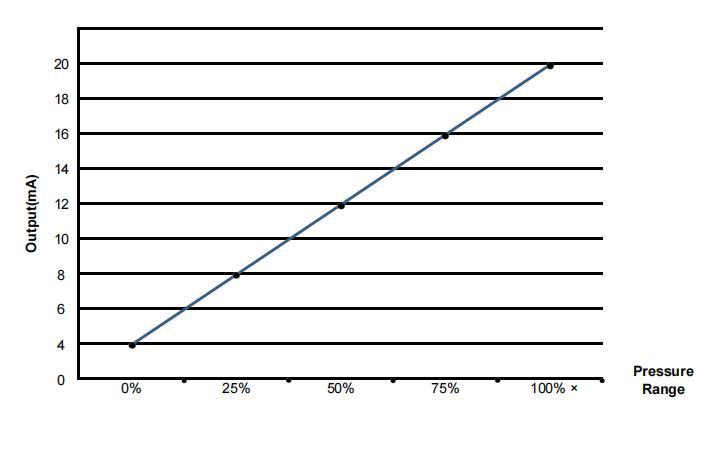

The intelligent monocrystalline silicon transmitter, leveraging advanced German MEMS technology, features a unique suspension design and sensor chip for top-notch accuracy and stability, even under extreme pressures. It integrates a German signal processing module for precise static pressure and temperature compensation, ensuring high measurement accuracy and durability. Capable of converting pressure into a 4~20mA DC signal, this transmitter supports both local (three-button) and remote (manual operator, software, smartphone app) operations, facilitating seamless display and configuration without impacting the output signal.

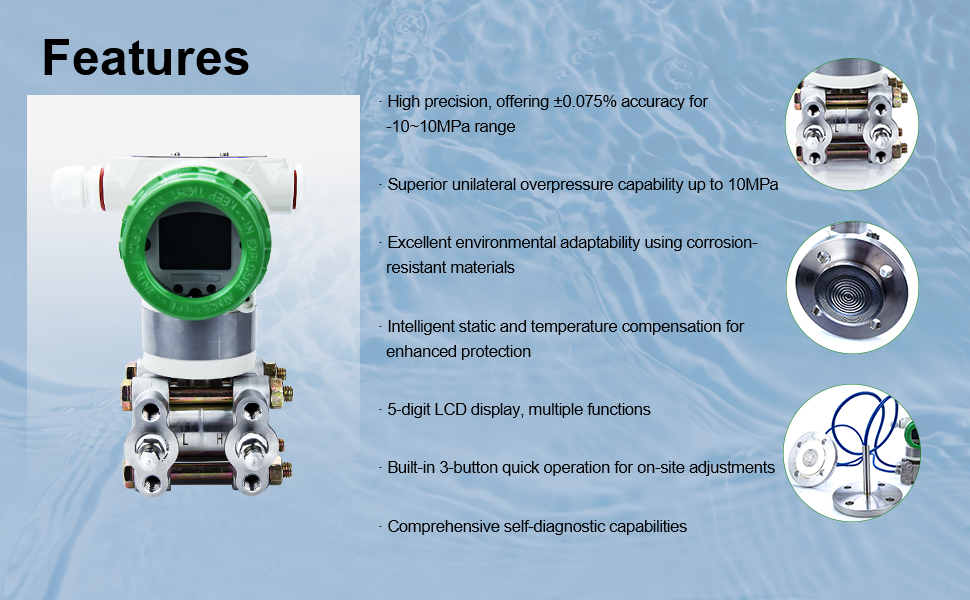

1. High Accuracy: Reference accuracy of 0.075% for standard calibration processes.

2. Exceptional Overpressure Performance: Capable of withstanding up to 16MPa of overpressure on minimal ranges.

3. Excellent Environmental Adaptability: Features intelligent static pressure and temperature compensation, minimizing measurement errors due to temperature, static pressure, and overpressure influences.

4. Superior Operability and Convenience: Equipped with a 5-digit backlit LCD display offering various functions (see selection notes), built-in three-button quick operation for local adjustments.

5. Corrosion-Resistant Materials: Available in various anti-corrosion materials.

6. Comprehensive Self-Diagnostic Functions: Ensures reliable and consistent performance.

1. Oil/Petrochemical/Chemical Industry: Paired with throttling devices for precise flow measurement and control. Accurately measures pipeline and storage tank pressure and liquid level.

2. Electricity/Urban Gas/Others: Requires high stability and precision for pressure, flow, and level measurements.

3. Pulp and Paper Industry: For pressure, flow, and level measurements in environments needing resistance to chemical and corrosive liquids.

4. Steel/Non-ferrous Metals/Ceramics: Used for furnace pressure and vacuum measurements, demanding high stability and precision.

5. Mechanical Equipment/Shipbuilding: Utilized in settings where stable measurements of pressure, flow, and liquid level are critical under strictly controlled conditions.

| Pressure range | -30~30bar | Pressure Type | Gauge pressure and absolute pressure |

| Accuracy | ± 0.2%FS | Input voltage | 10.5~45V DC (intrinsic safety explosion-proof 10.5-26V DC) |

| Output signal | 4~20mA and Hart | Display | LCD |

| Power impact | ± 0.005%FS/1V | Environmental temperature | -40~85℃ |

| Housing material | Cast aluminum alloy and stainless steel (optional) |

Sensor type | Monocrystalline silicon |

| Diaphragm material | SUS316L, Hastelloy HC-276, Tantalum, gold-plated, Monel, PTFE (optional) | Receiving liquid material | Stainless steel |

| Environmental temperature impact |

± 0.095~0.11% URL/10 ℃ | Measurement medium | Gas, steam, liquid |

| Medium temperature | Depends on flange | Static pressure effect | ± 0.1%FS/10MPa |

| Stability | ± 0.1%FS/5 years | Ex-proof | Ex(ia) IIC T6 |

| Protection class | IP66 | Installation bracket | Carbon steel galvanized and stainless steel (optional) |

| Weight | ≈6.98kg | ||

![XDB606-S1series Image[2]](https://j575.goodao.net/uploads/XDB606-S1series-Image2.jpg)

![XDB606-S1series Image[2]](https://j575.goodao.net/uploads/XDB606-S1series-Image21.jpg)

![XDB606-S1series Image[2]](https://j575.goodao.net/uploads/XDB606-S1series-Image22.jpg)

![XDB606-S1series Image[2]](https://j575.goodao.net/uploads/XDB606-S1series-Image24.jpg)

![XDB606-S1series Image[3]](https://j575.goodao.net/uploads/XDB606-S1series-Image3.jpg)

| Flat flange DN50 dimension table Unit: mm | |||||||

| Flange standard | A | B | C | D | T1 | Number of bolts(n) | Bolt hole diameter(d) |

| ANSI150 | 150 | 120.7 | 100 | 61 | 19.5 | 4 | 18 |

| ANSI300 | 165 | 127 | 100 | 61 | 22.7 | 8 | 18 |

| ANSI600 | 165 | 127 | 100 | 61 | 32.4 | 8 | 18 |

| ANSI900 | 215 | 165.1 | 100 | 61 | 45.1 | 8 | 26 |

| ANSI1500 | 215 | 165.1 | 100 | 61 | 45.1 | 8 | 26 |

| DINPN10/16 | 165 | 125 | 100 | 61 | 18 | 4 | 18 |

| DINPN25/40 | 165 | 125 | 100 | 61 | 20 | 4 | 18 |

| DIN PN 64 | 180 | 135 | 100 | 61 | 26 | 4 | 22 |

| DIN PN 100 | 195 | 145 | 100 | 61 | 28 | 4 | 26 |

| DIN PN 160 | 195 | 145 | 100 | 61 | 30 | 4 | 26 |

| Flat flange DN80 dimension table Unit: mm | |||||||

| Flange standard | A | B | C | D | T1 | Number of bolts(n) | Bolt hole diameter(d) |

| ANSI150 | 190 | 152.4 | 130 | 89 | 24.3 | 4 | 18 |

| ANSI300 | 210 | 168.3 | 130 | 89 | 29 | 8 | 22 |

| ANSI600 | 210 | 168.3 | 130 | 89 | 38.8 | 8 | 22 |

| ANSI900 | 240 | 190.5 | 130 | 89 | 45.1 | 8 | 26 |

| ANSI1500 | 265 | 203.2 | 130 | 89 | 54.7 | 8 | 33 |

| DINPN10/16 | 200 | 160 | 130 | 89 | 20 | 8 | 18 |

| DINPN25/40 | 200 | 160 | 130 | 89 | 24 | 8 | 18 |

| DIN PN 64 | 215 | 170 | 130 | 89 | 28 | 8 | 22 |

| DIN PN 100 | 230 | 180 | 130 | 89 | 32 | 8 | 26 |

| DIN PN 160 | 230 | 180 | 130 | 89 | 36 | 8 | 26 |

| Flat flange DN100 dimension table Unit: mm | |||||||

| Flange standard | A | B | C | D | T1 | Number of bolts(n) | Bolt hole diameter(d) |

| ANSI150 | 230 | 190.5 | 150 | 115 | 24.3 | 8 | 18 |

| ANSI300 | 255 | 200 | 150 | 115 | 32.2 | 8 | 22 |

| ANSI600 | 275 | 215.9 | 150 | 115 | 45.1 | 8 | 26 |

| ANSI900 | 290 | 235 | 150 | 115 | 51.5 | 8 | 33 |

| ANSI1500 | 310 | 241.3 | 150 | 115 | 61.0 | 8 | 36 |

| DINPN10/16 | 220 | 180 | 150 | 115 | 20 | 8 | 18 |

| DINPN25/40 | 235 | 190 | 150 | 115 | 24 | 8 | 22 |

| DIN PN 64 | 250 | 200 | 150 | 115 | 30 | 8 | 26 |

| DIN PN 100 | 265 | 210 | 150 | 115 | 36 | 8 | 30 |

| DIN PN 160 | 265 | 210 | 150 | 115 | 40 | 8 | 30 |

| Flat flange DN50 dimension table Unit: mm | |||||||

| Flange standard | A | B | C | D | T1 | Number of bolts(n) | Bolt hole diameter(d) |

| ANSI150 | 150 | 120.7 | 100 | 48 | 19.5 | 4 | 18 |

| ANSI300 | 165 | 127 | 100 | 48 | 22.7 | 8 | 18 |

| ANSI600 | 165 | 127 | 100 | 48 | 32.4 | 8 | 18 |

| ANSI900 | 215 | 165.1 | 100 | 48 | 45.1 | 8 | 26 |

| ANSI1500 | 215 | 165.1 | 100 | * | 45.1 | 8 | 26 |

| DINPN10/16 | 165 | 125 | 100 | 48 | 18 | 4 | 18 |

| DINPN25/40 | 165 | 125 | 100 | 48 | 20 | 4 | 18 |

| DIN PN 64 | 180 | 135 | 100 | 48 | 26 | 4 | 22 |

| DIN PN 100 | 195 | 145 | 100 | 48 | 28 | 4 | 26 |

| DIN PN 160 | 195 | 145 | 100 | 48 | 30 | 4 | 26 |

| Flat flange DN80 dimension table Unit: mm | |||||||

| Flange standard | A | B | C | D | T1 | Number of bolts(n) | Bolt hole diameter(d) |

| ANSI150 | 190 | 152.4 | 130 | 71 | 24.3 | 4 | 18 |

| ANSI300 | 210 | 168.3 | 130 | 71 | 29 | 8 | 22 |

| ANSI600 | 210 | 168.3 | 130 | 71 | 38.8 | 8 | 22 |

| ANSI900 | 240 | 190.5 | 130 | 71 | 45.1 | 8 | 26 |

| ANSI1500 | 265 | 203.2 | 130 | * | 54.7 | 8 | 33 |

| DINPN10/16 | 200 | 160 | 130 | 71 | 20 | 8 | 18 |

| DINPN25/40 | 200 | 160 | 130 | 71 | 24 | 8 | 18 |

| DIN PN 64 | 215 | 170 | 130 | 71 | 28 | 8 | 22 |

| DIN PN 100 | 230 | 180 | 130 | 71 | 32 | 8 | 26 |

| DIN PN 160 | 230 | 180 | 130 | 71 | 36 | 8 | 26 |

| Flat flange DN100 dimension table Unit: mm | |||||||

| Flange standard | A | B | C | D | T1 | Number of bolts(n) | Bolt hole diameter(d) |

| ANSI150 | 230 | 190.5 | 150 | 96 | 24.3 | 8 | 18 |

| ANSI300 | 255 | 200 | 150 | 96 | 32.2 | 8 | 22 |

| ANSI600 | 275 | 215.9 | 150 | 96 | 45.1 | 8 | 26 |

| ANSI900 | 290 | 235 | 150 | 96 | 51.5 | 8 | 33 |

| ANSI1500 | 310 | 241.3 | 150 | * | 61.0 | 8 | 36 |

| DINPN10/16 | 220 | 180 | 150 | 96 | 20 | 8 | 18 |

| DINPN25/40 | 235 | 190 | 150 | 96 | 24 | 8 | 22 |

| DIN PN 64 | 250 | 200 | 150 | 96 | 30 | 8 | 26 |

| DIN PN 100 | 265 | 210 | 150 | 96 | 36 | 8 | 30 |

| DIN PN 160 | 265 | 210 | 150 | 96 | 40 | 8 | 30 |

E.g. XDB606 – S1 – H – R1 – W1 – SS – C1 -G1 -D1 – A – X1 – DY – M20 – M – H – Q

| Model/Item | Specification code | Description |

| XDB606 | S1 | Single Flange Level Transmitter |

| Output signal | H | 4-20mA, Hart, 2-wire |

| Measuring range | R1 | 1~6kPa Range: -6~6kPa Overload limit: 2MPa |

| R2 | 4~40kPa Range: -40~40kPa Overload limit: 7MPa | |

| R3 | 10~100KPa, Range: -100~100kPa Overload limit: 7MPa | |

| R4 | 40~400KPa, Range: -100~400kPa Overload limit: 7MPa | |

| R5 | 0.3-3MPa, Range: -0.1-3MPa Overload limit: 7MPa | |

| Housing material | W1 | Cast aluminum alloy |

| W2 | Stainless steel | |

| Receiving liquid material | SS | Diaphragm: SUS316L, Other receiving liquid materials: stainless steel |

| HC | Diaphragm: Hastelloy HC-276 Other liquid contact materials: stainless steel | |

| TA | Diaphragm: Tantalum Other Liquid Contact Materials: Stainless Steel | |

| GD | Diaphragm: gold-plated, other liquid contact materials: stainless steel | |

| MD | Diaphragm: Monel Other liquid contact materials: stainless steel | |

| PTFE | Diaphragm: PTFE coating Other liquid contact materials: stainless steel | |

| Low Pressure Side Process Connection |

C1 | 1/4 NPT female |

| C2 | 1/2 NPT female | |

| High-Pressure Side Flange

Specification

|

G1 | GB/T9119-2010 (National Standard): 1.6MPa |

| G2 | HG20592 (Chemical Industry Standard): 1.6MPa | |

| G3 | DIN (German Standard): 1.6MPa | |

| G4 | ANSI (American Standard): 1.6MPa | |

| GX | Customized | |

| High Pressure Side Flange Size |

D1 | DN25 |

| D2 | DN50 | |

| D3 | DN80 | |

| D4 | DN100 | |

| D5 | Customized | |

| Flange Material | A | 304 |

| B | 316 | |

| C | Customized | |

| Diaphragm Protrusion Length | X1 | ***mm |

| Capillary Length | DY | ***mm |

| Electrical connection | M20 | M20 * 1.5 female with a blind plug and an electrical connector |

| N12 | 1/2NPT female with a blind plug and an electrical connector | |

| Display | M | LCD display with buttons |

| L | LCD display without buttons | |

| N | NONE | |

| 2-inch pipe installation

bracket |

H | Bracket |

| N | NONE | |

| Bracket material | Q | Carbon steel galvanized |

| S | Stainless steel |