A Ceramic Pressure Sensor Module is now a top choice for many industries because it is strong and very steady. Ceramic is a hard and clean material. It can handle heat, water, oil, steam, and chemicals without damage. Many factories use ceramic sensors in pumps, water lines, machines, and innovative tools. This is because ceramic does not rust and is not prone to bending. It provides accurate and reliable data for an extended period. It also works well in hot places and wet places. Many companies purchase pressure ceramic sensors from China manufacturers because they offer a reasonable price and good quality. These sensors last many years, so people trust them for safe and stable work.

Benefits of Using a Ceramic Pressure Sensor Module

A Ceramic Pressure Sensor Module is better than many metal sensors. It is made from strong ceramic that retains its shape even when subjected to sudden pressure changes. The pressure ceramic sensor provides a clean output, ensuring machines always receive the correct reading. The Ceramic Sensor Diaphragm is also very safe because it cannot rust. It does not weaken when it comes into contact with salt water, oil, or acids. This makes it great for pumps, pipes, water machines, food tools, and small OEM devices. It is also easy to install. It fits many boards and is compatible with various control systems. Many people choose it because it lasts long and has a low error rate.

Piezoresistive Ceramic Technology

The piezoresistive Ceramic Pressure Sensor Module works by bending a skinny ceramic layer. When pressure is applied, the layer bends slightly and alters the signal. This gives a clean and correct reading. A Piezoresistive Pressure Sensor made from ceramic is more steady than metal types. It remains strong when the temperature fluctuates rapidly. It also works well when pressure jumps many times in a row. The ceramic part does not deteriorate quickly, so the sensor provides the same reading for many years. Many brands use this technology for smart devices and water tools.

Corrosion and Chemical Resistance

A Corrosion Resistant Pressure Sensor is needed for water tanks, chemical plants, pumps, and oil lines. Ceramic is naturally safe against acids, salts, and strong liquids. It does not react with chemicals, so the reading stays correct. A Flush Diaphragm Sensor design also keeps the tip clean because nothing blocks the front side. This helps the sensor function effectively in mud, water, wastewater, or other thick fluids. It lasts a long time and requires very little care. This makes ceramic sensors a wise choice for many industries that need clean and steady results.

Stable Readings for Industrial Systems

A Stable Pressure Transducer is significant for pumps, blowers, factory tools, and big machines. Ceramic modules do not drift. They keep the same reading even after many cycles. They work well in low-pressure and high-pressure environments. They also exhibit very low noise, allowing the control system to receive a clean signal. This is why ceramic modules are often used as an industrial in this sensor. They work every day, for many years, without trouble.

Perfect for OEM and Custom Projects

Many brands want their own special sensors for their machines. An OEM Pressure Sensor with a ceramic inside is easy to adjust. The size, thread, signal, or range can be changed. A robust Pressure Industrial Sensor Module is compatible with pumps, smart IoT devices, meters, chemical systems, and HVAC units. With a ceramic material inside, the sensor remains safe even in heavy-duty work. It helps OEM brands build tools that last long and give precise data every time.

Reliable Ceramic Pressure Sensor Modules for Every Need

These Ceramic Pressure Sensor Module are strong and safe. They work in water, machines, and factories. They can handle low, medium, and high pressure and last a long time.

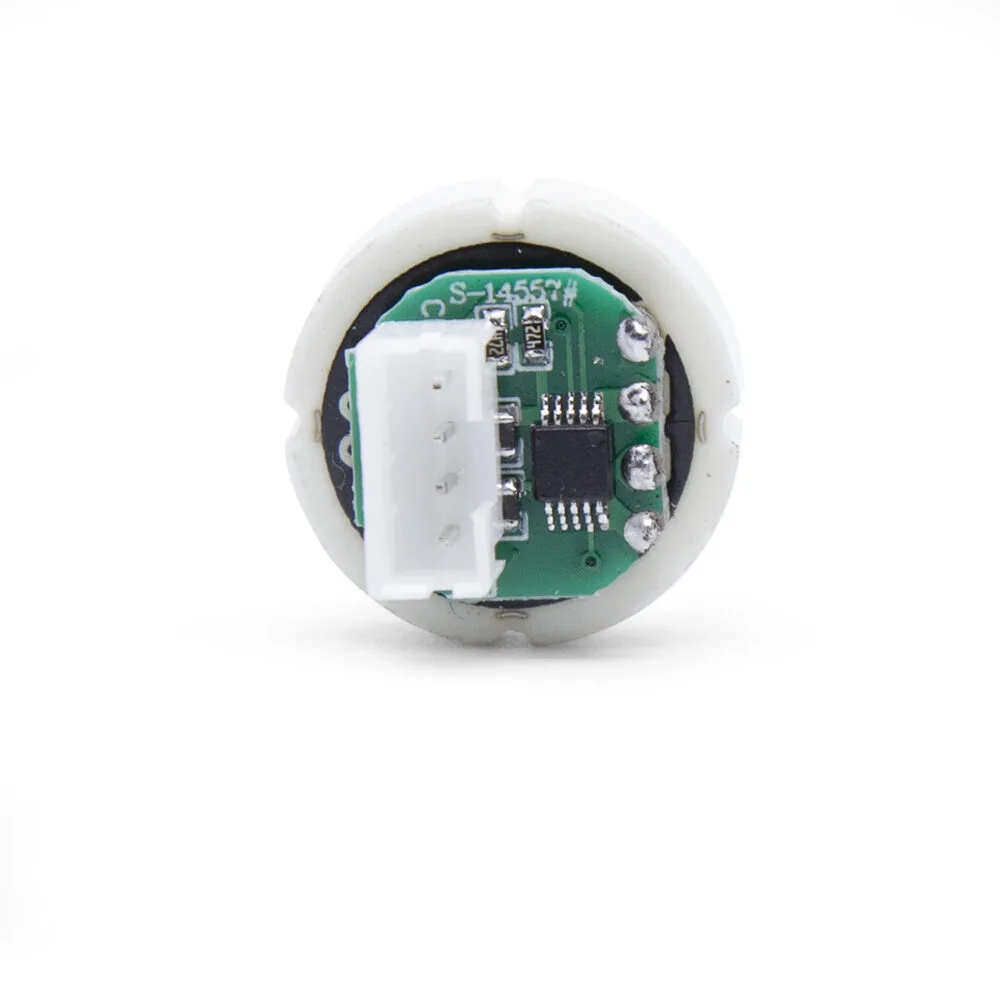

XDB103 Ceramic Pressure Sensor Module

The XDB103 Sensor Module is a robust and reliable sensor for various applications. It features a solid ceramic body that provides accurate data every day. It has a Ceramic Sensor Diaphragm that works well in water, gas, and light chemicals. It features a Flush Diaphragm Sensor on the front, ensuring it stays clean and prevents clogging. It is suitable for pumps, water tools, farm tools, and small machines. It handles shock and vibration well. The reading remains stable even when pressure fluctuates rapidly. It is a suitable choice for OEM systems that require low drift and a long lifespan.

XDB103-10 Ceramic Pressure Sensor Module

The XDB103-10 is a stronger type of these sensor modules designed for higher-pressure applications. It has a high-grade ceramic diaphragm that fights rust and acids. It is perfect for water plants, pumps, and pipelines. It utilizes a piezoresistive pressure ceramic sensor core, which provides a clean and stable output. It works in deep water or fast-flow systems because the ceramic body is resistant to bending or breaking. It lasts many cycles and gives steady results. Many OEM brands use it as a Stable Pressure Transducer in water and industrial systems.

XDB103-3 Ceramic Pressure Sensor Module

The XDB103-3 is a compact pressure industrial sensor module featuring strong and fast performance. It features a rigid ceramic body that remains clean and resistant to rust. It is suitable for water quality tools and pump systems. It utilizes a Piezoresistive Pressure Sensor core that maintains stable readings even when temperatures fluctuate. It is also easy to mount on IoT devices. Many users like it because it requires low maintenance and offers a long lifespan.

Choose Ceramic Sensors for Safe and Steady Results

Select your sensor today and enhance your system with XIDIBEI Ceramic Pressure Sensor Modules. Our sensors provide precise data, long lifespan, and safe operation in water, air, and chemical environments. Many people trust XIDIBEI because our ceramic parts remain strong in harsh environments. If you want a sensor that stays accurate and reliable, XIDIBEI is here to help. Explore our full range of these sensor modules. Find the one that fits your pump, machine, or project. Make your work safe, steady, and smart with XIDIBEI.

Ceramic Pressure Sensor Modules are used in water and machines. They last long, show the correct numbers, and do not break down in chemicals. People like them because they are reliable, strong, and durable, and they last for many years.

FAQs

What is a Ceramic Pressure Sensor Module?

A Ceramic Pressure Sensor Module is a device that measures pressure in water, air, or chemicals. It is strong, safe, and provides accurate readings for an extended period.

Where are Ceramic Pressure Sensor Modules used?

They are used in water systems, industrial machines, pumps, and OEM devices. They work well in harsh and wet conditions.

Why choose a ceramic sensor over a metal one?

Ceramic sensors last longer, resist chemicals, and give steady, correct readings. They do not rust or bend easily.

How long do Ceramic Pressure Sensor Modules last?

They can work for many years with low maintenance. They maintain stable readings even in the most extreme conditions.

Are ceramic sensors safe for use with chemicals?

Yes, they resist acids, salts, and other liquids. They stay accurate and clean in chemical environments.

What is a Flush Diaphragm Sensor?

A Flush Diaphragm Sensor has a flat surface that stays clean. It works well in water, mud, or thick fluids.

Can these sensors handle fast pressure changes?

Yes, ceramic sensors are strong and give steady readings even when pressure rises or drops fast.